Stucco (Italian: stuccatura, from stucco “gypsum, lime, alabaster”) is a finishing layer formed by hardened mortar. It is used for plastering walls.

The birthplace of plaster, like many other decorative coatings, is Italy.

Composition

The main components can be divided into: binders, filler, additives, solvent. Inorganic binders are used for the manufacture of stucco mortars: Portland cement, slag Portland cement, air lime, gypsum binders. Cement is used for all solutions used at a moisture content of more than 60% [comm 1].

Classification

Plasters can be classified by purpose:

- conventional (leveling) plasters - are intended for preliminary preparation of walls (creation of a flat, even surface for the purpose of subsequent application of thinner decorative coatings, painting, wallpapering) and protection of the external walls of buildings from environmental influences,

- special plasters - are used as insulating and shielding layers (sound-absorbing, fire-retardant, heat-saving, X-ray protective and others),

- decorative plasters - used in the finishing of walls, ceilings, structures to increase their aesthetic expressiveness.

Stucco can be classified into drywhen the surface is lined with prefabricated large-sized sheets (plates) of factory manufacture and monolithic (wet), which is carried out by applying a plaster mortar to the surface.

Depending on the class of the building (structure) and the requirements for the quality of surface finish, plaster can be classified into:

- simpleused in warehouses, temporary buildings and during subsequent cladding of wooden walls with tiled materials,

- improvedused in residential and public buildings of mass construction,

- high qualityused in buildings that are built according to individual projects.

Kinds

Decorative plasters, in turn, are divided into the following types:

- Colored plaster, which is ideal for finishing interior walls, door and window openings.

- Stone plaster, which in its appearance resembles natural stone.

- Venetian plaster. This type of plaster in its appearance resembles real marble.

- Sgraffito - this type of plaster got its name due to the features of the application.

- Terrazite plaster. This view is suitable for interior walls and facades.

- Silk plaster or liquid wallpaper - designed for interior use. Non-combustible, does not accumulate static electricity. The material consists of natural or synthetic fibers, mineral fillers and various decorative additives. It is applied with a plastic spatula to surfaces plastered and coated with a primer or oil paint. It has various colors and textures, has no smell, when applied, a seamless coating is obtained, the material is elastic and does not crack when the walls “shrink”. The main disadvantage is poor moisture resistance, but when treated with moisture-proof varnish, it can also be used in rooms with high humidity (kitchen, bathroom, and so on).

The most common conventional plasters are: mortar, cement-sand mortar, gypsum mixtures.

- Lime mortar They are mainly used for internal work, the main advantages of this material are the convenience and speed of its use during application, as well as maximum environmental friendliness. Among the disadvantages, a relatively low strength can be noted in comparison with other materials. The material consists of hydrated lime and river sand in a ratio of 1: 4, used with the addition of cement.

- Cement-sand mortars used both for internal and external work. The popularity is explained by the cheapness of these finishing materials. They are slightly more difficult to apply, but the coating is much stronger than when working with lime or gypsum mortar. The material consists of cement and sand in a ratio of 1: 4, for plasticity in small quantities add lime or PVA glue. Modern plaster mixes contain plasticizers, hardening inhibitors, water-holding and antifoam additives. Subject to application technology, the life of the finished coating exceeds several decades. Cement-sand mortars make it possible to smooth out shallow surface flaws (up to 20 mm deep, over 20 mm, reinforcing nets of braided type made of galvanized steel are used).

- Gypsum mixtures - are intended for internal work. Using gypsum mixtures, you can get a smooth coating of white color (or with shades of yellow, blue, pink, gray - it depends on the quarry in which the binder itself was mined). The main disadvantages of the material are its higher cost (10-15% higher compared to the cement mixture, 20-25% compared to the lime mortar), insufficient moisture resistance, the inability to use at operating temperatures below +5 ° C and relatively low strength . Also, in pursuit of a consumer who wants to save on a finishing thin-layer mixture, asbestos and other chemical additives unfavorable to human health are often added to gypsum plasters, which give the surface whiteness. However, gypsum plasters can significantly simplify the technological cycle of decoration and reduce the time spent on leveling the walls, which affects the popularity of these materials. The main advantages of gypsum plaster are high crack resistance, good adhesion to the base (adhesion to the surface being trimmed), the ability to spread thick layers in 1 pass without additional mesh reinforcement, low material consumption (bulk density of the dry mix is about 1000 kg / m3, for cement mix - 1600-1800 kg / m3), obtaining a smooth surface of the plaster coating (small grain size).

- Magnesia mixtures - are intended for internal work. Non-combustible, high-strength, non-dusting compositions for plastering the internal walls of rooms for painting, tile, wallpaper, etc. They belong to the category of non-dusting and non-combustible materials (combustibility category, GOST 30244-94 NG).

- Smooth Moroccan stucco - for its unique qualities found its way from Morocco, where the craftsmen passed its recipe and application technique from generation to generation for thousands of years.

Use in a modern interior

Recently, the use of decorative plaster in the interior has become an increasingly popular and common type of decoration. Today it is one of the best alternatives to wallpaper or walls for painting and the optimal solution for decorating a modern interior in a classic, Scandinavian style or, for example, for loft design. The composition perfectly "lays down" on drywall, concrete, brick, marble, wood, granite, leather and even fabric! A wall decorated with decorative plaster can be decorated with a bas-relief or by adding stones, shells or any other elements to the finished solution, depending on the composition and idea. Decorative plaster is natural, hypoallergenic, very unpretentious in care, has reflective properties, high vapor permeability, durability and mechanical strength.

Where plastering works, types of mixtures for plastering, technological drying times

Plastering works to align walls and ceilings in indoor and outdoor areas.

Advice! With significant deviations from the horizontal or vertical (more than 7 cm), it is cheaper and faster to use other methods of aligning walls and ceilings, for example, sheet materials or stretch ceilings.

Advice! With the help of ordinary plaster and your imagination, you can emphasize your interior and at the same time save on further decoration. To do this, you need a rope or rail, some stencil and your ideas.

Types of mixtures

- For leveling surfaces in wet rooms (bath, toilet, sauna, shower), cement-based mixtures are used, it is important !!

- For leveling surfaces on the street, cement-based mixtures are used for facade and street work with increased frost resistance, this is important !!

- For leveling surfaces in residential and non-residential premises, you can use both cement-based mixtures and more flexible gypsum mixtures, they are more expensive, but it’s more convenient to work with them, and further decoration will be easier.

On a note! The wall plastered with gypsum mixture is more prone to deformation and chips under the slightest mechanical impact. Roughly speaking, even small scratches will be visible.

Plaster mixes dry faster, a layer of 2, 3 cm. Dries about 10 days, a cement mixture of the same thickness will dry for at least 20 days. In any case, it will depend on humidity, temperature, the degree of ventilation of the room, the thickness of the layer, the base under the layer of plaster.

A change in the tone from dark to light indicates the drying of the surface of the walls. It is better to measure the percentage of moisture with a special device, with a moisture content of 8-9%, you can proceed to further decoration.

Plastering technology briefly

In order for the plastered surface to serve you faithfully for a long time, it is necessary to carry out all the work strictly according to the technology and adhere to the recommendations for starting work and drying the surface. Plastering technology briefly

Beginning of work

An acceptable temperature for starting work is 5-30 degrees, humidity is not more than 60 percent.

First, the ceilings are aligned, then the walls.

You will need the following tools: a construction trowel, a large spatula, as a rule, a gunny brush, a grater.

Work stages

- Surface preparation

Cleaning from dust, dirt, peeling, paint. If necessary, make notches on the concrete surface. - Plaster mesh installation or with a thick layer of more than 5 cm of a metal reinforcing mesh.

For better adhesion of the plaster layer with the base, fix the plaster mesh to the surface. - Surface priming primer.

- Installation of guide beacons

According to them, you can navigate when applying layers of the solution to the surface. You can use a profile attached to the wall with gypsum mortar. It is most convenient to install beacons using a laser level. - Wetting the surface with waterif not used priming.

- Spray

The device of the lower, rough layer of plaster, it should fill in all the bumps in the walls. The mixture is applied by spraying or spreading the solution with a more liquid solution. - Application and alignment.

We apply the main layer of plaster. It is applied after setting the lower layer of plaster. At this stage, a coating layer of the required thickness is formed, the mixture is used more dense. Align the solution to the beacons. - Grout.

Final surface alignment with a trowel. - Removing from the walls of lighthouses and filling the voids with a solution followed by grouting.

Proper drying of the surface after plastering

- Do not create drafts, but create conditions for normal air circulation.

- Do not use heat guns or heaters

- It is best to dry naturally, but if the weather conditions are insufficient, then additional heating with ventilation can be applied but no more than 30 degrees.

The plastering technology was briefly reviewed.

Features of plastering indoor surfaces

Stucco for interior work has a rather decorative role, but not a functional one. It has much lower requirements in terms of resistance to mechanical stress, the effects of moisture and water, temperature, reliability and so on. This makes internal mixes more affordable. In addition, they can be used to create high-quality, perfectly smooth surfaces that can later be tiled, painted, wallpapered or left without a decorative layer. There are several groups of materials for internal plastering.

Regular plaster

It includes three main types: gypsum, cement and lime plaster. The technologies for performing plastering works using these mixtures are similar, the differences are only in the method of preparation of the composition and its drying time.

Simple plaster is applied according to the following instructions:

- The first stage is spraying. For this purpose, use a solution whose consistency resembles sour cream. If a concrete surface is being processed, the plaster layer should be 5 mm, in the case of wood - 10 mm. The mortar is filled with a trowel in a trowel, after which it is “thrown” onto the wall. After several such “throws” it is necessary to level the surface and continue work on the remaining area of the wall, then leave it to dry.

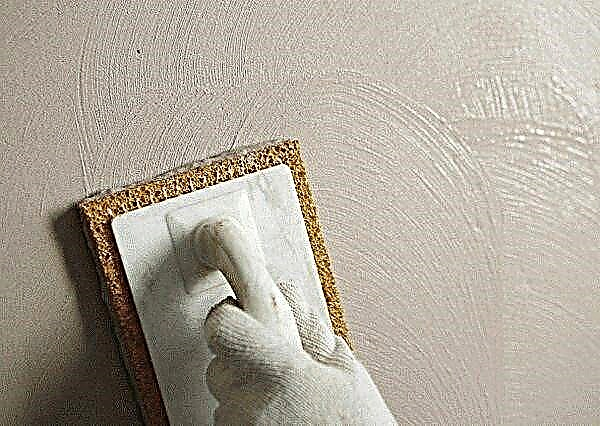

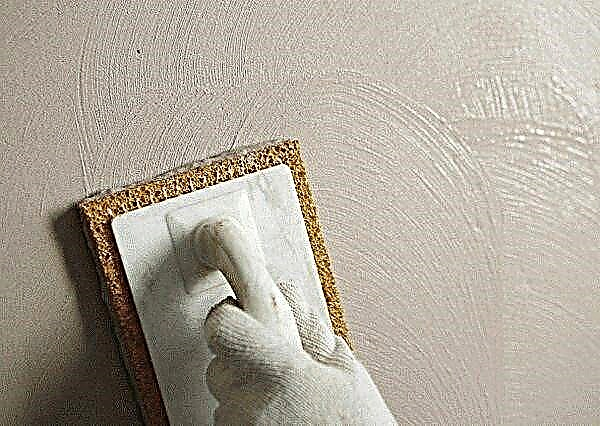

- The second stage is the application of soil. In this case, prepare a thicker solution resembling dough. It is applied only after the spray has dried. The plaster is applied in the same manner as the first layer, after which it is leveled with a long rule, moving from bottom to top. At the end, the treated surface is leveled with a grater in a circular motion.

- The third stage is a cover. This layer is decorative, its thickness should not exceed 2 mm. The previous layer should be slightly moistened with water, then trowel with a trowel and smooth it with a trowel.

- The fourth stage is grouting. This operation is carried out in two ways. In the first case, a wooden tool is used - a trowel. It is pressed tightly against the wall and perform circular movements. The protrusions are removed with a sharp edge. You can also use a grater, it is pressed to the surface and perform sharp movements back and forth.

It's important to know! At each of the above steps, it is necessary to check the evenness of the surface with a building level. It is also important to comply with all recommendations indicated by the manufacturer on the packaging.

Dry plaster

Dry plaster is a plasterboard. The basis of the material is gypsum, whose share is 93%. Conventional products of this type are covered with cardboard or paper, but for difficult conditions (fire hazard, high humidity) special materials are used. There are two options for applying this coating.

The technology for performing plastering works using glue includes the following steps:

- Preparatory. First you need to remove the old coating from the surface and tap its entire area with a hammer to identify unreliable fragments. All formed cracks and grooves should be filled with starting putty or cement-sand mortar. After that, the surface is cleaned with sandpaper and degreased. The surface to be treated is laid out taking into account the construction level, and then small fragments of sheet material are made, if necessary.

Preparing the wall for plastering. Application of primer. For these purposes, use deep penetration compositions that provide maximum adhesion of the material to the wall.The primer is applied with the help of a brush head - a special brush with a handle and thick bristles, after which they are allowed to dry (time is indicated by the manufacturer).

Preparing the wall for plastering. Application of primer. For these purposes, use deep penetration compositions that provide maximum adhesion of the material to the wall.The primer is applied with the help of a brush head - a special brush with a handle and thick bristles, after which they are allowed to dry (time is indicated by the manufacturer).

Primer surface. Glue application. You can glue the walls or each individual sheet of drywall. The second option is preferable, since each plate will be planted on a certain amount of glue, which is necessary by technology. According to the previously marked markings, the plates are installed one after the other, tightly pressing them to the wall. After finishing work, it is necessary to check the correctness of their conduct level.

Primer surface. Glue application. You can glue the walls or each individual sheet of drywall. The second option is preferable, since each plate will be planted on a certain amount of glue, which is necessary by technology. According to the previously marked markings, the plates are installed one after the other, tightly pressing them to the wall. After finishing work, it is necessary to check the correctness of their conduct level.

Glue application on drywall

Glue application on drywall

Important! Hanging furniture or appliances must not be installed on drywall.

Mounting the plate on profiles:

- The preparatory phase is similar to the first option.

- Installation of the frame. The first profile is fixed in the lower part of the wall near the floor, checking with the level. Then they put a vertical profile on one edge of the bottom rail and mark its highest point, the same thing needs to be done from the other end. Then connect the points in one line and set the upper profile along it. Two rails are connected by vertical profiles, fixing them with p-shaped brackets.

- Installation of sheets. Drywall is installed on the frame using self-tapping screws and a screwdriver.

- The last stage of work is the same as in the previous version.

Installation of drywall sheets on a metal frame

Installation of drywall sheets on a metal frameIt is recommended that a reinforcing mesh be installed before further finishing.

Basic information about the material and its features

Plaster is called a thick pasty mixture, which is created for the decoration of ceilings and walls in any room.

The stucco mixture for internal work can become both the basis for other finishing materials and the finish coating. Allows to eliminate even serious defects at the base. Finally, it becomes indispensable in the smooth leveling of surfaces, when later it is already painted, or finished with other types of facing materials.

Cement variety

Usually, cement-lime or cement-sand standard types of mixtures are meant. They are made with the addition of water, following certain proportions. An excellent option for processing rooms in which the high level of humidity is constantly maintained. This is true for the kitchen, bathroom.

Cement-sand plastering

Cement-sand plastering

Cement-sand types of plasters are often used to align walls, as well as when displaying surfaces to zero.

The main characteristics include the following characteristics:

- Low cost. Materials are available to literally every buyer.

- High adhesion. Thanks to the components in the composition, a high level of adhesion to the surface is ensured. It does not matter what material was originally made. It is not necessary to use a primer so that the surface has been pre-treated.

- Strength. Cement compositions outperform many other materials. A reliable coating appears on the surface of the walls.

But there are also disadvantages that also need to be assessed before acquiring.

- It takes 3-4 weeks to solidify materials.

- Plastering itself often becomes a very time-consuming process. It includes several stages at the same time. For each of them you need to spend some time.

- It is important to first accurately calculate what kind of load the walls will experience. It is necessary to carry out calculations on the thickness of the coating. Indeed, a significant mass is characteristic of cement options. This is important when using plaster for walls in the bathroom.

Plaster types of materials

Already by name it is easy to guess that gypsum acts as the main component. It is combined with lightweight fillers, due to which the material consumption becomes less. There are also modified additives of high quality. They are designed to increase the adhesion of the composition. The finished plaster for internal work has the same effect.

Gypsum plaster

Gypsum plaster

It is used to smooth surfaces before decorative finishes. Upstairs you can apply wallpaper, paint.

The benefits will be as follows:

- Environmental friendliness. Much higher than standard cement mortars.

- High vapor permeability. When the material hardens after application, it forms a porous structure. Due to what the surface will be able to "breathe". You do not have to worry about mold formation, even when the humidity level rises.

- Elasticity. Gypsum mixtures have good viscosity. Therefore, it is permissible to apply layers with a greater thickness on the surface. You can not be afraid of spreading, the appearance of defects.

- Missing shrinkage. What contributes to a perfectly smooth surface. In the process of solidification of the solution does not appear any cracks. This also distinguishes soundproofing plaster for walls.

Negative sides are also there, but they are fewer:

- Negative effect on objects made of metal during interaction. Actual for screws and nails, other elements. The process of rust is accelerated, structures become unsuitable for further use, while they are located in the thickness of the plaster.

- Unlike cement composition, strength is also at a lower level.

- The material can not be used when decorating rooms with high humidity. Better when another interior plaster is selected.

About polymeric materials

This material cannot be used when rough surface treatment is required. Most often, it is chosen for decorative functions.

The basis in the manufacture is polymer resins, or other substances of synthetic origin. In finished form, the plaster may have a plain or colored surface.

The benefits include the following features:

- Resistance to low temperatures.

- A large number of finishes.

- Resistant to moisture.

- No need for additional decoration.

- Drying is quick, even. It turns out a smooth and smooth material. And the internal plaster of the walls becomes the best means of protection.

Properties of silicone compounds

In such circumstances, silicone resin mixed with various types of fillers becomes the main component. Usually their role is played by substances of the mineral group, or tissue aggregates.

The composition adds components that contribute to the improvement of strength. They also protect materials from changes in temperature, high differences in humidity.

Decorative finishing using this material is carried out on almost any basis.

Among the advantages that these types of plaster mortars possess are:

- Good vapor permeability.

- Good adhesion.

- The durability of the coating. Service life reaches 25 years under all conditions.

- Water resistance.

- Elasticity. Ready-mixed plasters for interior use often have this advantage.

There are only two drawbacks. This refers to the high price level combined with the need to carry out pre-processing. During it, silicone primers are used.

The usual group of plasters

It includes three subgroups: high-quality, improved, simple.

- Simple plasters have two main layers - this is soil and spray. Together, their thickness reaches 12 millimeters, no less. The best option when decorating rooms in which no one lives. Similar circumstances can also influence the choice of plaster for interior use.

- There are already three layers in improved plasters. In addition to the two listed, another nakryvochny is added to the composition. Such a coating has a thickness of 15 millimeters. The surface requires final leveling, smoothing using the rule. Plaster is suitable for both residential and public buildings.

- High quality plaster. When finishing in this case, spray is first used, then two layers of primer are applied, then there is a coating. The finish has a thickness of 20 millimeters. Alignment is carried out when using beacons, the coating is processed with a grater. The best option for those who plaster multi-storey residential buildings, as well as public institutions.

Decorative varieties of material

Here are what types of plaster are when separated by this principle.

Embossed. They help to create various patterns and drawings on the surface. The option of creating imitation of other materials is allowed. A suitable option for interiors of any kind, because there is a wide selection, both in color and texture. Crumb, quartz or granite, marble is often added to the composition.

Mineral Such compositions contain components such as metal particles, marble in granules and silica sand. Thanks to this, the coating looks like an expensive stone cladding. The most famous varieties of decoration are called fur coats and bark beetles. The first is characterized by the presence of a coarse-grained structure.

Venetian plaster moisture resistant for interior use. The main component is dust, which itself is quartz or marble, granite. In addition, crumbs of the same stone as dust are added. Dyes and binders can give the product a finished look. The texture is similar to granite, soft velvety, translucent.

Selection recommendations

The choice of plaster should be given special attention, because it depends on how much the material will last. It is only necessary to understand what materials and with which surfaces they perform better.

If walls with aerated concrete are plastered, care must be taken that the pores on the surface are not clogged. Otherwise, the vapor permeability will be broken. Cement-sand mortars are not suitable. It should be borne in mind that special anti-vandal plaster for walls is also available.

The best solution for aerated concrete - stucco mixtures based on gypsum. The finished layer will pass water vapor through itself, which helps to maintain the level of vapor permeability.

Gas silicate blocks involve the use of a slightly different technology in the manufacture. But the cellular structure of the material is very similar to the same aerated concrete. Therefore, finishing can be done with gypsum plaster. Dry plaster for walls quick-drying with a lime-gypsum composition is one of the acceptable options.

Additional information

Each variant of the mixture has its own composition and its own characteristics, which differ from other varieties. Good adhesion along with low weight is the characteristic most relevant for the foam block. You can give preference to materials sold in finished form.

Home-made solutions do a good job with wood options. Astringent components can be different:

Clay and lime are currently used less frequently than others. Although among their advantages, the presence of antiseptic properties is noted, high rates of thermal insulation.

Hard putties are a more expensive option, but you should not refuse them only for this reason. After all, this material for plastering walls indoors gives good results.

Coating and finishing mixes

The coating mixture can also be called a leveling option. The purpose is to prepare the surface for decorative materials of other varieties. Plaster materials belong to this group. The coating layer becomes a kind of intermediate option.

Finishing coatings are the most expensive of all, but the attractive appearance pleasantly surprises customers for a long time. The texture, structure are compiled on the basis of various additives, fillers. Finishing types are much more often used for outdoor work. Do-it-yourself plaster is also suitable for this, the types of mortars and plasters may be different depending on the work being carried out.

Stucco Tips

First of all, you need to find uneven areas. For this, plumb, water levels will become indispensable assistants. Marks are made using a marker. In addition, you need to mark the wall in order to then put beacons on it. Work starts from the corner, with a slight indent of 0.3 meters. You need to draw a vertical line at the very beginning. 1.6 meters - the optimal distance between the beacons.

Special holes with a drill are created at a distance of up to 15 centimeters from the ceiling. Dowels are inserted into them, and then with the help of devices they pull the ropes. From the other side of the wall, the action repeats.

The surface is treated with 1-2 coats of primer to improve adhesion. Partitioning continues when the primer dries completely. Several vertically stretched ropes are fixed with screws. These are great landmarks when the wall is leveled.

Conclusion

Using plaster indoors with your own hands is a rather time-consuming process. But the application technology cannot be called too complicated. Only decorative varieties of materials require a greater level of skill. But a similar problem can be solved independently if you try.

Application on simple surfaces

Do-it-yourself plastering work is carried out in the following order:

- First you need to apply a layer of ordinary starting plaster and let it dry. This is necessary to remove bumps and other surface defects.

Application of leveling plaster

Application of leveling plaster

The formation of the pattern of decorative plaster

The formation of the pattern of decorative plaster

Painted decorative plaster

Painted decorative plaster

To save time and effort, you can use a figured roller. First, do all the basic steps that are indicated above, after which the roller is rolled in a container with a solution and put it on the wall. The result is a surface with a relief pattern. In the end, it will be necessary to treat the wall with acrylic wax.

Plasterboard application

The use of decorative plaster for coating gypsum plasterboard surfaces is not always advisable. Using this material, it is recommended to correct only small defects or equip the so-called "color zones" in the premises. The application technology is similar to the processing of concrete surfaces, but has the following features:

- The solution dries in about a week.

- The layer should be as thin as possible.

- Pre-treatment of the surface with a primer is required.

- The solution is applied in a circular motion.

You should know! Most decorative mixtures dry quite quickly, so it’s better to prepare small portions of the solution to avoid solidification in the container.

What should be the materials

Modern building materials of this type are made on the basis of cement or lime with the addition of various additional components that are necessary to improve the performance of the resulting surface.

Facade plaster is exposed to atmospheric influences and temperature changes, therefore, its choice should be taken very seriously

Facade plaster is exposed to atmospheric influences and temperature changes, therefore, its choice should be taken very seriously

They must have the following properties:

- Resistance to temperature changes, moisture and wind.

- Good ventilation. A quality coating should be well ventilated so that moisture does not accumulate under it. Otherwise, the plaster will simply fall off after a short period of time.

- Frost resistance. This indicator is especially important for territories with a cold climate. The fact is that prolonged exposure to low temperature can lead to cracking of the material.

Important! It is recommended that you buy only certified products from sellers who can provide quality certificates.

Facade technology

First of all, the surface must be leveled and cleaned of possible contaminants. This is followed by actions that are similar to applying conventional plaster (see above). Spray is applied, after two days the soil, and after 2 weeks a coating. The thickness of the layers is 0.5, 2, and 0.5 cm, respectively.

Plastering the exterior walls of the house

Plastering the exterior walls of the house

During the finishing work on the external walls, weather conditions must be taken into account. If it began to rain, then the work needs to be postponed, and also add 1-2 days to the drying time of the plaster.

- If there is an old layer of plaster on the external walls, then it is necessary to choose the most similar material in composition.

- In order to avoid cracking of the material, it is necessary to start work only after complete shrinkage of the structure. Depending on the method of construction and building materials that were used for the construction, shrinkage can last from six months to five years.

- Only use special tools for applying the mortar to the facade.

All types of plastering work are quite simple, while they do not require expensive construction equipment. Therefore, most home masters prefer to perform them on their own.

If you have confidence in your abilities and a desire to do the work yourself, then adhering to the application technology and following the above rules, as well as the manufacturer's recommendations, will allow you to perform plastering at the highest level. Otherwise, it is better not to tempt fate, but immediately turn to specialists to avoid unpleasant consequences.