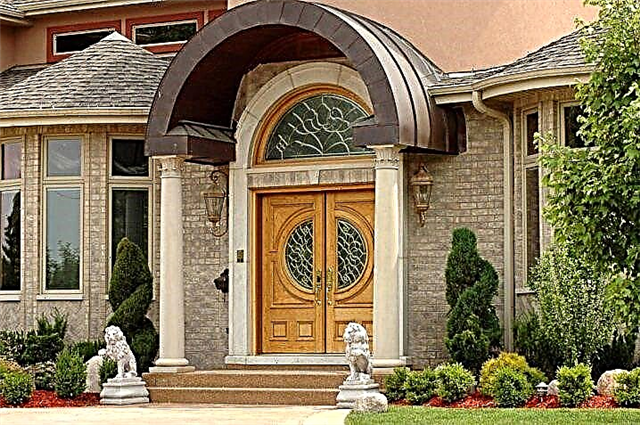

The brick fence is strong, durable and suitable for any site. It can be made in the form of a solid wall, but in most cases a combination of brick pillars and openwork spans of wood or metal is used.

Brick fence is made:

- ceramic brick

- clinker brick,

- from silicate brick.

For the construction of the fence, a brick of classic red color is most often chosen. But recently, brick fences of yellow, blue, white and other colors are gaining popularity. You can even choose a texture: smooth, corrugated or rough.

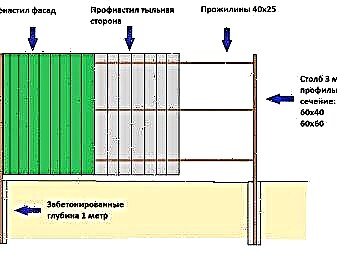

The main structural element of the brick fence is the support pillars, regardless of whether the fence is completely built of brick or spans of metal or wood will be used. Pillars can have different parameters depending on the size of the brick from which they are built. For example, the most commonly used bricks are 250x120x65 mm in size, which gives columns with a cross section of 38x38 cm. All brick pillars have a metal column with a cross section of 60x60 mm at the base.

Metal fence

Metal fencing is equally often installed both at production facilities and in private areas. The reasons for their popularity are availability, durability and a large selection of designs:

- sectional

- from corrugated board,

- from the netting.

Sectional Metal Fence

This type of fence is installed in parts on support pillars made of stone or metal. In most cases, the design of the fence is assembled before fixing to the supports, which significantly saves time. Sectional fences can be welded or cast. The first are made of individual metal elements, which are given the necessary shape, after which they are welded onto the design of the fence. The second are cast sections made of steel or cast iron, which can be solid or lattice.

A more expensive variant is a forged fence. Art forging allows you to create an original fence with any pattern, but its cost is an order of magnitude higher than that of the other two types of fences.

Varieties of sectional fences

For the manufacture of sectional fences, various materials are used. The most popular is ordinary metal, from which welded sections are created. But for these tasks also use:

And other options suitable for creating off-the-shelf components. To install products in place, additional materials such as concrete, brick, metal structures and the like are used. This allows you to create a reliable fence, the characteristics are not inferior to a full-fledged fence.

For the construction of such fences, ready-made components are used - sections. They are used for cottages, country houses, private areas, construction and other fences as a temporary and permanent solution. Now there are several common types of sectional fences:

- Sectional Wooden Fence

It has a nice view and low cost. Wooden fencing is easy to build and allows you to quickly fence the territory. But its reliability is low, and for long-term use requires special care for the wood.

Low price, reliability and simplicity - the advantages of a fence made of mesh netting. It practically does not differ from the usual options from this grid, therefore, it took all the advantages of such designs. Elementary maintenance, low cost of materials and high installation speed make this type very popular.

- Fencing

Decking is a good material for sectional fencing. It is initially produced in sheets, so you can immediately order suitable sizes. It is easy to install, has a low cost, and also hides everything that happens behind it. It is often used as a permanent solution, but for this it is worth choosing a quality professional flooring.

- Welded Sectional Fences

This type of metal fence is the most popular. He uses finished metal products such as fittings, forging, shaped pipes and the like. Such structures are durable, often have a pleasant appearance, and are also easy to install (if you have experience in welding). But their cost is higher than that of conventional partitions.

- Concrete sectional structures

Today it is a popular and optimal type of fencing. The advantages of concrete are that it is a reliable, long-term and inexpensive material. In addition, decorative segments are often created from it, which initially have a special texture and additional elements. This makes such a fence very beautiful, which makes it permanent. But decorative concrete products are expensive, and working with them is quite difficult due to the weight of the sections.

These are all the most used sectional fences that can be found on the market today. Each of them has its drawbacks and advantages, so it’s worth choosing them depending on the requirements and tasks.

Another type of such fences is noted - brick. But this is a misconception, because sections of brick are not produced, but are erected in place by ordinary masonry. Sometimes you can see special brick columns for installing segments, but there is no full-fledged brick segment on the market.

Features

Such a fence is quite difficult to break and bend

Welded and mesh sectional fences are ideal for different types of sites. Additional requirements are put forward for the metal, because in the future it should not suffer from the negative effects of the atmosphere. To do this, manufacturers apply a special composition over the finished elements.

The hedge has an attractive appearance. Welded modules differ in ornament and height. Installation requires the installation of supports. They are subsequently attached to the mesh elements in the finished form. Thanks to this, it is possible to significantly accelerate the process.

Types, advantages and disadvantages

A wide range of welded fence sections allows you to choose the perfect option even for a fastidious client. Products have occupied their segment and continue to gain popularity. The following advantages of the welded structure are distinguished:

- Customers like the attractive appearance of the finished construction.

- Each element is tempered in a special furnace. The process can significantly increase the life of the fence. Hardened metal does not suffer from the negative effects of precipitation.

- Also, the advantages for customers are ease of assembly and the absence of the need for special equipment.

- Sections are highly durable. They will be able to break only with strong mechanical stress.

- A quality fence prevents unauthorized entry. However, the owner will need to correctly calculate its height.

- Consumers are also attracted by the durability and aesthetics of the design. It retains color and shape over a long period of time.

Among the shortcomings, we note the high cost. Cons also lie in the fact that the fence is difficult to paint. People will see what is happening inside the site. However, the high price is combined with a long service life. That is why welding fences are considered fully paid back.

Before buying and choosing a specific design, it is recommended to analyze the main types.

From fittings or profiled pipes

In the budget version, reinforcement is used as the material of the section for the fence. She will not be able to protect the territory from dust, but is suitable for determining the boundaries of the site. Installation does not take much time. Through the use of a metal profile, it is possible to give the fence a concise appearance. Additionally, it is possible to install a raised surface.

Sectional

A welded sectional view of the fence will protect property from the outside world. There is a possibility of manufacturing according to individual parameters of the customer. The fittings and pipes are placed in a pre-constructed frame. Ease of installation is often used to equip plots with office buildings. At the same time, it is possible to maintain the necessary level of view of the area.

From the net

Mesh fencing is universal and can be used in any terrain. The selection of such welded sections on the fence is advisable to make if it is important the penetration of light into its territory. The enclosed area will receive a sufficient amount of sunlight. Thanks to this, it will be possible to plant individual plant species in the flower beds.

Sectional mesh fencing

A sectional fence from a mesh netting is the simplest fence, which is installed where the enclosed area needs free access to light. The density of the mesh cells allows the use of the fence as a designation of the territory or as a barrier against the penetration of animals. Such a fence does not give a shadow, does not protect from wind, noise, and prying eyes. However, it is quite appropriate where the yard is surrounded by a hedge.

The sectional fence from the netting netting loses aesthetically to other fences, but withstands competition with them in cost. Providing a decent supervision of the condition of the fence, it is possible to operate such a fence for several decades.

Metal sectional constructions

Sectional fences made of metal profile are easy to install, reliable and durable, low price. Sections of this type of fencing are distinguished by the variety and size of the section. Such a fence is easily installed on rough terrain in places where there are height differences. The structures are fastened to the support posts by welding, they do not require additional care.

Decking is currently considered the ideal material for the construction of fences. This material can be installed without a frame, but designed in a section, it acquires rigidity, which allows the fence to withstand very strong winds. After proper installation and painting of welding spots with an anti-corrosion compound, the fence does not require maintenance for many years. Occasionally, once every several years after inspection, previously painted surfaces are renewed. Such fences serve more than half a century, without losing their aesthetic appearance.

Metal Sectional Fences-Blinds

Solid metal fences are an obstacle to the wind, this has a bad effect on the microclimate of the fenced area. The air in the closed area stagnates, sometimes damp appears moss, and unwanted insects start. Designers created fence sections in the form of blinds. The fence-blinds consists of metal strips mounted on a frame. Such a fence closes the territory from prying eyes and does not create obstacles to the movement of air, it lets in diffused sunlight, which is very important for plants growing near the fence.

Openwork fences

A metal fence made of openwork sections combines strength, aesthetics and a century of service life. Although such a fence does not cast shadows, it always adequately complements the architectural composition of the enclosed area and reliably protects the territory from uninvited visitors.

In addition to metal openwork sections, sectional fences from concrete panels of complex patterns appeared on the construction market. Concrete openwork sections can be said to be cheaper than all existing fences, but they are heavy and fragile. For their installation, lifting equipment is required, but they are assembled for a long time.

Section fence installation rules

Any model of the fence from the sections has a common build option. For the installation of sections, prepared support columns are required, placed at a certain distance from each other, to which the spans of the fence are attached. Any fence has a gate and a gate. There is an opportunity to select their sizes for each customer individually for their fencing.

For the installation of fences from the sections, it is not necessary to install the foundation, however, for their installation, the support posts are preferably concreted into the soil. With such an installation, they withstand the load of the weight of the fence spans attached to them. This is especially necessary for continuous fences, such sections are subject to windage.

Key design features

Metal support posts are square and round, cut from shaped pipes of the right size. Upper and lower sections are hermetically sealed at all poles to prevent moisture from entering the column.

Transverse segments are welded onto the posts in two places for fastening the intake sections.

Metal sections are made in sizes from 60-290 cm in width and from 150-200 cm in height. The frame is made of a profile pipe 40x20 mm. In the internal space of the frame various inserts are fixed, it can be a mesh-net or complex metal openwork.

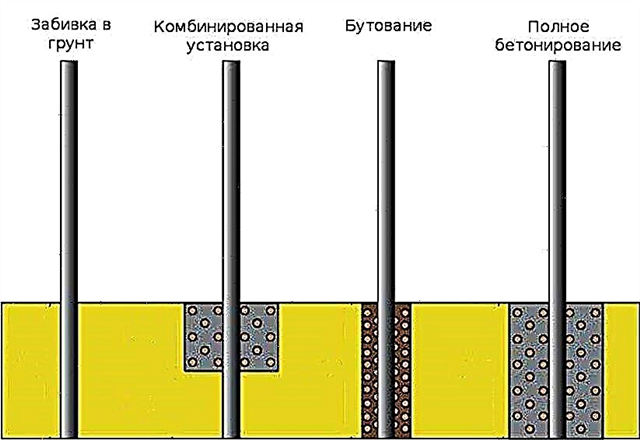

Installation of support posts

First of all, it is necessary with the help of a rope and pegs to mark the territory to be protected. Using a stretched rope, measure the length of the entire fence and mark the places for installing the supports, taking into account the dimensions of the sections that will be fixed to them. The posts are clogged or screwed to a depth of more than a meter. The method of installation of the supports depends on the density of the soil, the weight of the panels, the pressure force of the winds.

Pillars are clogged into soft or loose soils, while the underground part of the posts should be at least 1.5 m, and the sections should be ventilated.

Methods of mounting posts for the fence

Pillars with separate concreting of each supporting pillar are installed in dense and dry soil. For each column, dig a hole with a shovel. To speed up the process and facilitate the work, a screw screw manual or mechanical screw is used.

The hole is drilled to a depth of 1.3 m, crushed stone with sand 5 cm thick is poured into the bottom. Rubble and sand must be compacted. The support in the pit is installed strictly vertically, the framework of the reinforcement is laid, the pit is poured with a solution of concrete. After pouring the solution, the columns are left for concrete to solidify.

If the soil in the enclosed area is too wet, then the support pillars are installed with the so-called tape filling. For such a foundation, they dig a trench in which the formwork is placed, the posts are hammered at the right distance and poured with concrete.

The depth and width of the strip foundation under the support posts is selected depending on the massiveness of the intake sections. The heavier the sections, the wider the foundation tape.

Making various fences in sections allows the owners of the sites to stand out among the neighbors, choosing the type of fence according to their taste and installing it with their own hands.

Frequently Asked Questions and Answers

To date, cadastral work and their result is a document that is an electronic form, an approved form (Xml-scheme). Any result of cadastral work can be signed with the electronic digital signature (EDS) of the applicant, which will allow the copyright holder not to spend time visiting the MFC to transfer a package of documents for cadastral registration or registering the right to a property, but send an electronic document via the Internet to Rosreestr. To make an electronic digital signature, you must contact any certification center involved in the manufacture of qualified certificates of electronic signature verification keys (KSKP EP), in accordance with Federal Law dated 06.04.2011 No. 63-FZ "On Electronic Signatures" for Rosreestr.In the manufacture of KSKP EF for individuals and legal entities, a special information encryption algorithm is used that excludes the modification of a document signed with such an electronic signature.

The procedure for coordinating the boundaries of a land plot is established by 221-ФЗ dated 07.24.2007. and is mandatory if cadastral work is carried out, as a result of which the location of the boundaries (s) of the land plot in relation to which the work was carried out, or of land plots adjacent to it, information about which is entered in the Unified State Register of Real Estate, is specified:

1) property

2) lifetime inheritable possession,

3) permanent (unlimited) use,

4) leases (if such adjacent land plots are in state or municipal ownership and the corresponding lease agreement is concluded for a period of more than five

The procedure for coordinating borders includes: 1) Notification of all interested parties, 2) conducting coordination of borders and drawing up an act of coordination.

Notification of owners of adjacent land plots can be carried out both individually and by holding a meeting on the coordination of the location of borders and by publishing in the media in the manner established for the official publication of municipal legal acts. The publication of the notification on the coordination of borders is carried out in the absence of information in the USRN about the contact addresses of interested persons.

You can read in more detail in this article the link.

From 01/01/2017 there was a unification of the procedures for cadastral registration and registration of rights of real estate objects in accordance with the effective Federal Law-218 of 07/13/2015. "On state registration of real estate." It will now be possible to issue a real estate object at one stage of the transfer of a package of documents by the copyright holder to the authorized federal bodies to carry out a set of procedures and obtain as a result of extract from the USRN the registered right. To date, this procedure, unfortunately, has not been technically implemented by Rosreestr, but according to information provided by the Ministry of Economic Development, the possibility of simultaneous cadastral registration and registration of rights is planned for July 1, 2017.

In the case of the formation of a land plot from lands owned by state or municipal property, in accordance with the Land Code, a land plot is provided on the basis of the layout of the land plot on the cadastral plan of the territory. The location scheme on the CBT has an approved form in accordance with the orders of the Ministry of Economic Development and can be prepared both in electronic form and in paper form. The electronic form is the format of the Xml-scheme and is signed by the electronic signature of the authorized local government. Provision of a land plot on the basis of the location scheme on the CBT is carried out for plots provided for gardening, personal subsidiary plots, individual housing construction.

After paperwork (preparation of a technical plan or land surveying), a package of documents is sent to Rosreestr through the MFC. The registrar checks the availability of documents, their compliance with the established forms, the correctness of the specified information. If he finds obstacles to registration, he makes a decision on suspension, which he informs the applicant about. To clarify the reasons for the suspension, and to decipher the bureaucratic phrases that suspension usually dashes with, you should contact the cadastral engineer who created the documents. Three months are usually available for changes. You can read more about suspensions and the reasons for their receipt here.

The inability to read a disk, certified by the electronic signature of the cadastral engineer, on the device of the MFC or the registrar of the Rosreestr is one of the reasons for the suspension of cadastral registration. However, the problem is often not a disk or reader defect, but other nuances, which are reflected in more detail here. To solve this problem, you should again contact the cadastral engineer who was preparing the package of documents, and he will rewrite the disc for you.

What is it like?

A sectional fence consists of a certain number of blocks assembled together thanks to various connection elements. The main advantages include:

- ease of installation without the involvement of specialists,

- cheaper than most types of fences,

- decent appearance

- large variation of materials.

Columns are used as a fulcrum and a reference point for each section. They should be fixed in the foundation, and sections - hanging on poles. This saves time, effort and reduces the amount of foundation.

There is a wide variety of sectional fences. The differences are in the material from which it is made, as well as in additional elements. They are used to create a stronger and more beautiful fence.

The most common option is to use in sectional fencing mesh netting. Its basis is galvanized wire. You need to know that there are grids of different quality. Also, the width of the cells may be a factor. For fences near the plants, a large width is chosen to obtain the maximum amount of sunlight by the plants. The cell density often does not even create a shadow.

This option is easy to install and cheap enough.. These two factors determine the popularity of mesh-netting. Also, the mesh is durable, reliable and easy to maintain. With proper installation, it will not sag for a long time. And with the optimal choice of height, no animal can penetrate your territory.

More expensive is welded mesh option.

Such a fence has several advantages over a fence with a mesh-netting:

- higher strength. It is achieved due to the fact that the fastening of the elements is due to spot welding - this allows the use of such a fence for a long time,

- various diameters of metal bars. This allows you to change the density of the bars,

- elimination of the possibility of sagging sectional fabric,

- creating a 3D effect due to the presence of one or more V-shaped protrusions.

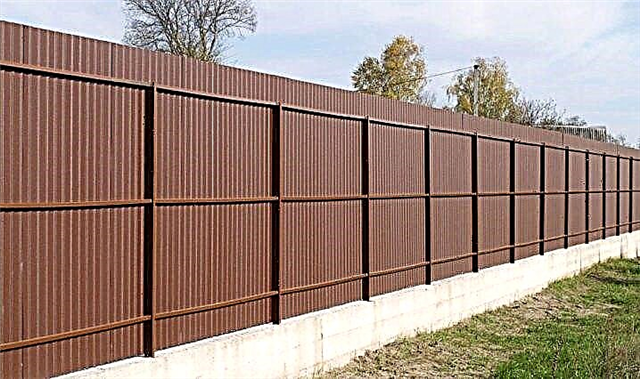

Easy to manufacture is the option of fencing from corrugated board. Such a fence will help to hide everything from the eyes of neighbors and passers-by. Decking looks good, there is a wide selection of material colors. Due to the fact that the supports are concreted, this type of fence will be reliable. This also eliminates the windage of the sheets.

The only thing that you may need from you during operation is to monitor the material and paint the sheets of corrugated board. They lose color from constant exposure to ultraviolet radiation.

Wooden sectional fences are easy to assemble and install. In appearance, such a fence may not be the most sophisticated, more often it is chosen for any landscape or for the embodiment of any design ideas. The main thing is to correctly make all measurements, then correctly perform the installation of such a design. If all conditions are met, then such a fence will last an extremely long time.

A very popular, durable and strong option is the manufacture of elements and sections from a metal profile. Different patterns can be executed in each section. Great for places with large elevations. Special care during operation is not required. Installation is carried out by welding sections on supporting poles, therefore this design will serve for a very long time.

One of the options may be a metal fence, most often it is an aluminum sheet. If you make sections all-metal, due to the lack of ventilation, air stagnation occurs. This can lead to waterlogging of soils, the appearance of mosses, and an increase in dampness.

These factors will increase the number of insects on the site. Therefore, when choosing metal fences, it is best to choose blinds and fences.

They consist of a large number of panels mounted on poles. They are capable of transmitting a small amount of ultraviolet rays. Constant air circulation also occurs. Thanks to a certain angle of inclination, panel elements will perfectly protect the territory from uninvited guests and from unnecessary views of neighbors.

The most sophisticated - fences with forging elements. With the help of openwork elements, you can safely create any plexus. Also forged metal is resistant to any kind of impact. The appearance of such fences will delight you and your neighbors.

Reinforced concrete fence looks very reliable, here you can also show creativity when decorating. Such a fence is represented by blocks from 50 to 200 cm wide, which are superimposed on each other. The weight of each element is 50 - 75 kg, so three workers can cope with the installation of such fencing without the use of special equipment.

Mounting

During the preparatory phase, before installing a new fence, you need to know exactly what tool you have. The necessary tool will be:

- electric drill or screwdriver,

- welding machine,

- Bulgarian,

- hammer drill.

Also required:

- metal pillars or supports,

- self-tapping screws and other hardware,

- corners for the frame,

- cement-sand mixture.

The first and main stage is the marking of the area under the supports. The posts should be strictly vertical - the quality of work and the aesthetic appearance of the entire fence will depend on this.

Under each support it is necessary to dig a hole with a depth of 45 - 60 cm. It is best to use bricks so that the pole is clamped and almost does not move. Verticality must be constantly checked by level.. After all the preparatory steps, you can pour the concrete mixture into the pit. It is best for some time to maintain the pillar yourself until the moment the concrete has dried out the slightest. After that, verticality is checked again. And such an operation must be carried out with each column.

After installing all the poles, you can attach the finished sections to the supports.

It is best to lay bricks under the structure, so as not to hold the heavy structure with your hands for a long time.

Benefits

The popularity of sectional fences is due to a large number of advantages:

- a huge selection of decorative elements, a large selection of colors,

- a large selection of sizes and types of sections,

- Fire safety,

- reasonable price, affordable to many consumers,

- practicality,

- long service life

- the ability to swap designs

- ease of installation,

- high strength

- often - light weight of the entire structure (with the exception of reinforced concrete structures),

- ease of maintenance.

The durability of any type of sectional fence depends on the quality of work.

To put a sectional fence with your own hands is a fairly feasible task. Sometimes it may take more time to choose the material, shape and size of the sections. The attractive price allows the use of such structures everywhere, and the simplicity of installation work will please anyone, even a beginner in the construction business. The main thing to remember is that the durability of the entire structure will depend on the quality of all parts, as well as the quality of the work..

You will learn how to install a sectional fence correctly from the following video.

Fence from corrugated board

Decking is a convenient and lightweight material based on durable steel that is resistant to difficult weather conditions. Each sheet of corrugated board is painted and treated with special chemical components that provide protection against corrosion. Coloring elements are polymers that are resistant to direct sunlight, chemicals and moisture. The fence, painted with polymer paint, does not burn and does not change color for many years.

The advantages of a fence from corrugated board:

- ease of installation - installs faster than fences made of brick or natural stone, and does not require special equipment,

- small weight - 1 m2 with a thickness of 0.5 mm weighs only 4.7 kg,

- the ability to connect with other building materials, including mesh netting,

- environmental Safety,

- a large selection of colors and patterns with imitation of stone, wood or brick.

Fence from corrugated board involves supporting structures. The most reliable option is supports made of metal pipes, to which side mounts and mounting brackets are welded. Cross braces are used to provide strength and increase rigidity. The fact is that in windy conditions the fence from the corrugated board is experiencing increased loads, and without additional support the sheets will bend and deform.

Cross fasteners are made of square pipes with dimensions of 40x40x2 mm or 1.5 mm for a standard sheet of corrugated board of 1 m2. If necessary, sheets are ordered in individual sizes, which ensure the strength of the fence in places with natural bumps or incline.

Chain-link fence

The mesh netting has been used for the construction of fences for more than two centuries and is valued for its ease of installation, weather resistance and low cost. Mesh Material:

To protect against corrosion, a polymer or zinc coating is applied to the mesh depending on the application.

Installation of a fence from a mesh-netting does not require significant earthwork, it is enough to install supporting posts. The recommended distance between the intermediate supports is 2.5 m. Depending on the needs, this distance can be reduced or increased by half a meter, but 2.5 m is considered the best and safest solution.

The distance between the racks plays an important role in the installation of the fence, as it guarantees its stability in strong winds, heavy rainfall, mechanical stress. If the fence is longer than 25 m, additional support posts with double brackets must be installed.

The height of the posts depends on the height of the fence and how they are installed. If the grid is mounted on poles embedded in the foundation or concrete, they should be 25-30 cm higher than the fence itself. If the columns are dug into the ground, their height should be 50 cm above the fence. When mounting the grid on the anchors, which is the fastest and most convenient way, the height of the rack should correspond to the height of the fence.

Wooden fence

Wooden fences fit well into the landscape of both the village and the city. All elements are made of healthy, seasoned wood, treated from fungi and insects. The most preferred types of wood for the construction of the fence remain oak, elm and larch. Ash, alder, aspen, pine, spruce and fir are less preferred, and building fences from linden, poplar, willow and birch is not recommended. During the construction of the fence, the wooden elements that will be immersed in the ground must be additionally treated from decay.

In traditional wooden fences, the cross sections of pillars are usually 60x60 mm or 80x80 mm. Wooden panels are mounted on brick or concrete supports, and then fastened with metal anchors. The optimum thickness of the boards is 25-38 mm, and the width is 5-15 cm.

Forged

Welded section for the fence can be not only smooth. Through special manufacturing, welding allows you to get an unusual shape of the element. Thanks to this, it will be possible to make the fence not only functional, but also beautiful. Forged welded structures will last a long time using high-quality metal. A special composition is applied on top for added protection.They do not clutter up the territory, and the low noise level during installation allows the process to be carried out at any convenient time.

With decorative inserts

With decorative inserts, the design will look different. They are also used to decorate gates. The fencing from the welded sections will look more elegant. With the correct selection of the height of the fence, it will also perform a protective function. The design of the fence depends on the financial capabilities and individual taste of the owner.

Installation tips

Installation of sectional fencing is carried out in several stages. This will require a small amount of time, because individual parts of the structure are sold immediately ready-made. The installation process is short if you follow the instructions:

- The foundation for the fence rummages in a carefully cleaned and marked area.

- Equally important is the choice of a support pipe of a suitable diameter. It must support the weight of the fence and not warp.

- To place supports under the bearing parts, dig holes and fill them with concrete.

- Each pillar is placed in a hole and waiting for fixation. It is advisable to put spacers up to the moment of solidification. The column is placed in a hole and the general level of the structure is checked. It should not twist when assembled.

- From the following supports, the same distance along the entire perimeter should be noted.

- The section is fixed to the frame using special elements.

To increase the life of the fence after installation, it is recommended to cover it with a protective composition. This will significantly increase the service life and prevent the surface from suffering from negative external influences. If desired, can be dyed in any color.

Sectional Fence Installation

The installation of such a fence consists of several stages, including preparation, excavation, placement of the fence and the final stages. Although sectional fence is simple, the process may seem difficult for a beginner. Therefore, it is worth doing it according to plan.

The work consists of the following steps:

- Setting marks under the posts.

You must first measure the entire working area and determine the exact location of the pillars. Marks will simplify further work.

- Excavation.

This stage includes work with the soil and its preparation. It is necessary to determine the shortcomings of the territory (the depth of freezing of the soil, its stability and the level of groundwater) and carry out the appropriate work. They include drainage, the creation of drainage channels and the like. - Foundation preparation.

The preparation of the foundation for the pillars is an important step in determining the stability of the entire structure. It is necessary to create a well, followed by backfilling of crushed stone and ramming. Building sand will improve the stability of the column. - Installation and concreting of pillars.

The first two pillars are installed and concreted. It is important to put them evenly, because otherwise the partition will not. - Placement of the first section.

The first partition is installed on the first two columns. - Further assembly.

The first section continues further work.

The construction takes several days, after which the quality of work is checked. And for a more accurate explanation, you can watch a video of the installation of a concrete sectional fence: