Against the backdrop of the abundance of proposals for finishing materials for facades, one of the most traditional ways of creating a protective and decorative coating on the wall is plastering. Perhaps it will seem to someone archaic and ineffective. But according to unofficial statistics - the opinion of those who are building, for every third house in low-rise private construction, it is precisely the plaster that is used as the facade decoration.

Cement-lime plaster

Stucco facade: technology benefits

All modern materials for facade cladding have one rather significant advantage, thanks to which they are widely used, despite their unnaturalness, so to speak - this is a simple and quick installation, which practically does not require special qualifications. In this regard, the decoration of facades with stucco, of course, loses, because this process is quite long and laborious. It is for this reason that in order for a person to freely give up all kinds of innovations, one needs to get acquainted with the advantages of "outdated" technologies. What gives us the use of plaster for facade decoration?

- A reliable and durable surface that can easily withstand all weather disasters and careless handling of a person. Remember, at least, decorative plaster applied on polystyrene foam - one cannot even lean on the wall normally, not to mention what happens to such a facade with a light blow by any object. At least a dent, and as a maximum damage, which is very troublesome to fix.

- Breathable walls. The normal moisture exchange of brick or concrete walls with air is very important for the home - thanks to it, such structures last much longer.

- Lack of toxic secretions. No matter how the manufacturers of newfangled finishing materials claim that their products are absolutely harmless to humans, it is difficult to believe in it, since only chemical products are used for their manufacture. Let's look at things realistically - all modern composite materials are made either entirely from plastic or using it. Also, in their manufacture, the case is not without glue compositions, which are by no means useful to humans, even after drying.

Sand and cement are another matter - if everything is done correctly and withstands the technology of facade plastering, then you will get an environmentally friendly, and most importantly, durable coating, which can later be decorated in any way you like. I agree, the work is not easy, and it’s already difficult to find good specialists. In general, the time has come to master this profession on your own - especially since it does not differ in particular complexity.

DIY facade stucco photo

How to plaster a house facade: sequence of work, subtleties and nuances of technology

In order to better understand the technology of facade plastering, we will divide it into three main stages - reinforcement, installation of beacons and the actual process of plastering. They will have to go through if you decide that this is the best option for your home.

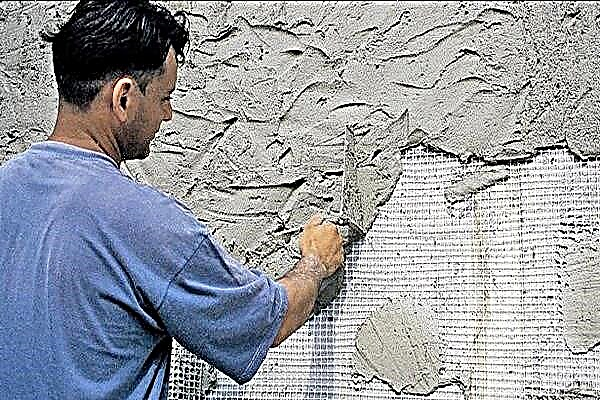

- Reinforcement. According to all building codes, plaster is reinforced only if the layers of the applied mortar are more than 3 cm. Forget about these standards and consider the installation of a metal mesh (namely, we will use it) as a means of ensuring increased durability of the facade finished in this way. In general, we will use reinforcement in any case. The best option is a metal mesh with a mesh size of 10x20 or 20x20mm and a wire thickness of 1-1.5mm. It is attached to the wall with dowels, which are installed from each other at a distance of 200mm. You can definitely not measure it out - nothing bad will happen if they are installed a little more often or less (better often). Everything is simple here, and there are no subtleties - we take a punch and fix them.

How to plaster a house facade

Stucco facade lighthouse photo

Grout plaster photo

So, step by step, strip after strip, the facades of the house are plastered. After the solution is completely dry, its surface is abundantly opened with a primer (in two layers), and then painted or covered with decorative plaster. By the way, painting the facade with stucco will not be the right decision, if you want to get a really beautiful surface, it is better to putty the plaster with a thin layer before painting.

Facade plastering technology

As you can see, plastering the facade, as, in general, and any walls of the house, is not a difficult process - rather, it can be called time-consuming, as you will have to work hard physically. In all other respects, this is a fairly simple job, which, if desired, can easily be learned to perform independently.

Features

When constructing a country house or repairing a building according to a design project, the responsibility of choosing a stucco mixture for decorating the facade rests with the shoulders of a professional architect-designer. The specialist is able not only to choose a beautiful color, but also take into account the characteristics of the material in order to maximize the individuality of the structure and not exceed the estimate.

Various types of stucco mixtures for outdoor use have some similar characteristics, among which:

- The ability to create a durable and at the same time “breathable” coating of the external walls, under which condensation does not accumulate.

- High elasticity of the compositions, which makes it possible to apply it to any fantasy wall options.

- Good adhesion to various substrates (subject to application technology).

- High resistance to humidity, UV rays, temperature extremes.

- The presence of compounds that perform the function of insulation.

- Excellent decorative qualities.

- Long service life and easy care.

- Environmental friendliness.

- Possibility of quick application.

Facade plasters are usually divided into 4 categories, depending on the basis of which substance they are made. These are the following varieties:

- Mineral based on a cement mixture.

- Acrylic plaster based on the resin of the same name.

- Silicate, at the base of which are compounds called liquid glass.

- Silicone (polymer), made on the basis of synthetic silicone resins.

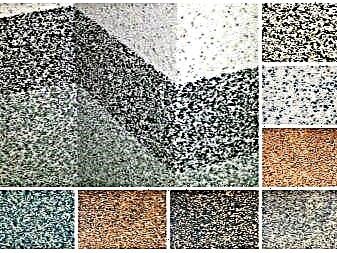

Variants of mixtures are also distinguished by their decorative qualities. The most famous are “bark beetle”, “fur coat” and “lamb”. Recently, “pebble” and “mosaic” plasters have become popular, which allow you to create an unusual and even exquisite design of facades and basement foundations.

Modern manufacturers produce decorative plasters on various bases: they contain mineral, silicone or acrylic binders. However, regardless of the type of base, the common name of the mixture forms a similar coating texture due to the presence of the same decorative fillers in the composition.

The terrasite plaster, which is widely used for decorating facades, which is based on a mineral mixture, looks particularly attractive thanks to interspersed additives such as marble, glass and mica.

The facade is coated with decorative terrazite plaster, reflects and refracts the sun's rays, this visual effect looks very advantageous.

To insulate the walls from the outside, vermiculite plaster is used, having a bulk filler - vermiculite in its composition, due to which the thermal conductivity of the walls covered with this composition is significantly reduced.

Application area

A private house, the facade of which the owners wish to plaster, can be built from various materials: from cast concrete, brick, aerated concrete, wood or stone. For each type of wall, you must select the appropriate type of stucco mixture.

There are facade plasters that are applied on top of insulation and are perfectly fixed to mineral wool, polystyrene and polystyrene foam.

Based on the recommendations of the manufacturers indicated on the packaging and the practical experience of professional builders, the following recommendations can be made:

- On mineral substrates (including GCR and mineral wool), silicate plaster will hold perfectly.

- All types of plasters are suitable for gas and foam blocks, brick and concrete, however, it is worth considering the fact that some manufacturers, for example, Ceresit, produce a mixture that is most adapted to cellular concrete work.

- For exterior wooden walls or OSB boards, gypsum compositions are contraindicated. The use of a cement-sand mixture is recommended. Also, acrylic facade coating and some varieties of silicone or silicate plaster are used on wood.

- Ventilated facades with insulation can be plastered with silicone, acrylic and silicate compositions, not forgetting the need to use the appropriate primers and building mesh, to ensure maximum adhesion to the base.

- Even a metal surface, for example, a channel can be plastered, the main thing is to clean and degrease the metal well, fix the plaster mesh to the surface and be sure to prime it before applying the composition.

Consumption per 1 m2

Works on the decoration of the facade should be divided into 2 stages:

- Alignment of the walls.

- Applying decorative finishes.

Using facade plaster, an experienced craftsman, when leveling the wall surface, is able to eliminate significant differences and hide small defects. However, in these cases, the flow rate of the mixture increases, and calculating the required amount is not an easy task. To facilitate the calculations, it is customary to initially calculate the consumption of the stucco mixture per 1 m2. This task is performed by installing beacons. There are several ways to install beacons, but it is most convenient to use steel corners from 35 mm to 60 mm in size and a plaster rule for this purpose.

First, the rule with the built-in level determines the deviation of the wall from the vertical. Then prepare a plaster mortar, which is applied to the surface of the corner. The corner is pressed against the wall and leveled according to the level, in the necessary places placing a solution under it.

The higher the lighthouse is, the more mortar you have to spend on leveling the wall. The next beacon is installed at a distance of 130 cm (in the case when the master works by one and a half meter rule).

The vertical between the lighthouses must be checked according to the level, while the rule should not knock on the lighthouses, and there should be no gaps between it and the lighthouses. The more often lighthouses are installed, the more accurately it will be possible to calculate the arithmetic average value and determine what the mixture flow rate should be for leveling 1 sq. m. When the beacons are installed, it is necessary to measure the maximum and minimum layers. The minimum layer starts from 5 mm (the thickness at which the beacon is closed with a solution), the maximum can be quite significant and depends on the curvature of the wall. Between these indicators, the arithmetic average of the thickness of the plaster layer is calculated.

On the packaging of any plaster mixes, the approximate flow rate required for applying a 10 mm coating layer is always indicated. Based on this value, the required flow rate is calculated for each specific case. Suppose, if the average thickness of the plaster layer is 25 mm, then the manufacturer's figure of the flow rate of the mixture should be multiplied by a factor of 2.5.

The decorative coating, which is applied over the leveling plaster, most often has a thickness of not more than 10 mm, so its consumption corresponds to the value stated on the package.

What is a plaster, or "wet" facade

Plaster is a layer of hardened plaster mortar, applied in a plastic state to the surface in several stages (depending on the thickness of the layer) with compaction and smoothing. A layer of plaster levels the surface of the walls. Applied in a sufficiently thick layer, it also serves as an additional heat insulator of the facade, making the house warmer in winter and cooler in summer.

The characteristics of the plaster coating depend on the composition of the mortar: its layer can be vapor permeable, that is, the surface under it "breathes", and at the same time is very durable and has excellent waterproofing characteristics. And besides, plaster opens up the widest possibilities for decoration: remember, most of the historical buildings in our cities are plastered. A variety of cornices, moldings, vertical and horizontal traction, sandriks, rustics and other elements of the classical style are made of ordinary plaster based on cement and lime.

The plastered facade. St. Petersburg

One of the positive qualities of this material is the ability to create a seamless coating over the entire area associated directly with the base. There is no need to introduce various fasteners that create areas with different heat capacity parameters (“cold bridges”). Applied without technology violations, the plaster retains all its qualities for a long time, protecting the construction of walls, warming the building and decorating it.

Stucco creates a seamless coating on the wall

Stucco facade options overview of the main types

Various methods of plastering are known, but in order for the final result of any of the options to fully satisfy, you should achieve the following qualities:

- the material must have high throughput, the scientific name of this quality is vapor permeability, it will depend on this whether condensation will appear, whether the building will be protected from moisture penetration inside,

- the material must have a certain resistance to moisture, that is, have the ability not to absorb moisture in sizes leading to destruction,

- ease of application - this is a very important requirement for every material of external plastering, most of the buyers put it at the forefront,

- material cost - a determining factor in price and quality, which makes it possible to use the composition in places with difficult weather conditions,

- material color - is determined by personal preferences and overall impression, the harmony of the general form.

It is very important to make the right choice and take into account the peculiarities of weather and terrain. The durability and quality of the plastered facade will depend on how the selection of material is carried out correctly.

Be sure to consider such factors:

- seasonal temperature fluctuations,

- humidity and proximity of water bodies,

- the proximity of highways

- the prevalence of low or high temperatures.

Regardless of the choice, the plaster must bear all of these factors.

Plaster mortar differs in the main component - the binder component. To date, such varieties of plaster for building facades are known:

- mineral

- acrylic

- silicate

- silicone

- with stone chips.

Make a decision only after analyzing all the features and taking into account the pros and cons of each option.

Do-it-yourself mineral plaster for the facade

It is possible to make a solution for plastering the facade with your own hands or from dry material packaged in bags that is produced at the enterprise.Making the mixture with your own hands will significantly save money, but the slightest error can lead to disastrous results. Therefore, the purchase of the finished mixture is an option that will not let you down, moreover, it is less energy and time consuming.

The options for plastering the facades of mineral-based houses have several advantages:

- low cost of material

- good adhesion of the mixture to the surface base,

- high strength indicators

- good vapor permeability

- low moisture absorption

- high resistance to low temperatures,

- resistance to temperature extremes.

Of all the existing options, mineral finishing mixtures are the most budget. But this option of plastering has a number of weaknesses:

- it is impossible to paint the mixture in the state of solution, but only after application with facade paint,

- slight choice of color for coloring,

- low elasticity - cracks form at the slightest shrinkage.

Do-it-yourself silicate plaster

Silicate compositions for external use are used very often. The mixture is applied in a thin layer, since it implies the parallel use of mineral wool insulation.

The advantages of silicate plaster are:

- high degree of vapor permeability,

- dust repellent ability of the mixture,

- moisture resistance

- does not fade

- resistance to mechanical stress,

- ease of maintenance.

But this option has disadvantages:

- expensive material

- without work experience, it is difficult to apply the solution yourself,

- heavily removed if necessary.

DIY facade stucco

Among all the existing options for plastering the facade, silicone plaster is considered the most high-quality and durable. Despite the high cost, silicone mixtures are used, as they provide a finish for a long period of time without restoration and repair.

The advantages of this finish can be called:

- dust repellent abilities,

- moisture resistance

- plastic,

- does not fade in the sun

- retains its properties over a long period of time,

- high resistance to mechanical stress,

- applicable to any surface, has a high degree of bond.

The disadvantages of this option are:

- the high cost of the material

- complexity of application

- low vapor permeability.

This option has proven itself in an area with high temperature fluctuations.

DIY acrylic facade plaster

Acrylic mixtures have good technical indicators: they are flexible and wear-resistant. It is necessary to carry out preliminary preparation in the form of leveling the surface. Rough leveling requires cement mortar, especially for new buildings, which will certainly shrink. Acrylic plaster will not crack in this case, as is the case with mineral composition. But the option with the use of an acrylic mixture also has disadvantages:

- expensive material

- has a low fire safety quality,

- low vapor permeability, additional ventilation is required,

- absorbs dust, which is removed with great difficulty.

Do-it-yourself insulation under the facade plaster

To insulate the facade under the plaster, mineral wool, polystyrene or other similar materials are used. For such heaters it is recommended to use an alkali-resistant fiberglass mesh.

The insulation work is as follows:

- the insulation is attached to the wall surface with glue or special dowels,

- a layer of glue is applied to the insulation and the net is embedded in it,

- heat insulation and mesh are covered with a solution

- apply decorative plaster on top.

The main steps for plastering the facade with your own hands

To plaster the facade with any of the options, it is necessary to perform a series of sequential actions:

- prepare the surface of the building, clean the dirt, embroider the seams,

- primed walls or treated with special disinfectants,

- special mesh reinforcement,

- installation of beacons,

- applying a mixture for plaster,

- grout.

Some experts advise using reinforced meshes only in cases where the layer thickness exceeds three centimeters, but it is better to use a mesh for any thickness. It helps to improve adhesion and is the prevention of cracking. For each version of the facade plaster, one or another kind of mesh is used:

- galvanized steel mesh,

- alkali resistant mesh.

Do-it-yourself wet stucco facade

Stucco wet asphalt is considered one of the most effective for warming the facade of the building. You can prepare the mixture yourself or buy a finished one, here everyone proceeds from their capabilities and preferences.

Any construction technique has its advantages and weaknesses. Also, wet plaster has lists of advantages and disadvantages. Let's consider both those and others in more detail.

Advantages of wet facade plaster:

- does not occupy additional space, does not make a residential building visually “thicker”,

- has a long service life, on average up to thirty years, the facade looks beautiful, does not need to be repaired or updated,

- does not increase the load on the structure,

- soundproof

- reduces the thermal conductivity of the building,

- wide selection of color palette.

But this option has certain disadvantages:

- in the process of plastering and until the material dries completely, it is necessary to protect the surface from dust, which can significantly impair the appearance of the home,

- work can only be done in the warm season,

- if the material has not yet “grasped” the appearance of the facade may suffer from precipitation, it will take several days to harden,

- plastering at high air temperatures is also extremely undesirable, the solution will dry out and crack.

The process of applying plaster is quite simple: a layer of wet plaster is applied to the insulation.

There are a large number of options for plastering the surface of the house. Everyone chooses the best option, taking into account the terrain, weather conditions, budget and personal preferences. Both an experienced craftsman and not quite an experienced craftsman will be able to do the main work.

If you still have questions about how to plaster the facade with your own hands, watch the video. There you will find the most important structured information regarding the features of plastering facades with your own hands.

Types of modern facade plasters

All types of plaster mixes available on the construction market are divided into three large groups.

- Ordinary. The main purpose is to level and protect surfaces from external influences.

- Decorative. For the finish - creating a beautiful finish.

- Special. Their purpose is also protection, but not from ordinary rain or snow, but from increased penetration of water (waterproofing), heat and sound insulation, from mechanical stress (reinforced) and even from the effects of radiation.

Plaster is used to level and protect the surface of the wall.

Also, plaster compositions differ in the type of binder.

Cement, cement-lime and lime

The most common and inexpensive conventional facade plaster is cement based. It fully meets all the requirements for covering facades. Lime plasters are also suitable for outdoor use, but they are less strong and moisture resistant compared to cement-based mortar.

To increase the plasticity of the cement-sand mortar, lime is added to it. And to make lime plaster more durable and moisture resistant - cement. The result is a compromise solution: a durable and moisture-resistant coating and a solution easier to use - cement-lime plaster.

Application of cement-lime plaster. Photo from vidyotdelki.ru

The composition of traditional lime, cement and cement-lime plaster mortars was previously regulated by various GOSTs. Today, many varieties of ready-mixed dry mixes based on cement and lime are produced, and the plasticizers introduced into their composition improve the characteristics of the plaster layer and facilitate its application.

In our market you can ask the price and choose the right mixture for finishing work. Take a look at the selection of Dry building mixes.

Clay

In the wake of the popularity of green building among modern homeowners, there is an interest in the traditional, but in recent years, not very common material for plastering facades - clay.

Old clay plastered house

In a natural clay solution, in addition to clay, natural additives are present - ash, coal, chopped straw or sawdust. Fermented grass infusion (similar to the one used by summer residents to feed their plants), horse manure, animal urine and blood, and whey were used as natural plasticizers.

Modern house, plastered with clay mortar. Photo from pajaconstruction.com

For those who care about the environmental safety of their homes, natural stucco can be bought in the same way as regular - in the form of a dry mixture. It already contains all the necessary and natural additives and plasticizers that make the clay moisture resistant. Therefore, a house with a facade plastered with natural material is not afraid of rain and can be built not only in regions traditional for adobe construction with a dry and hot climate.

Acrylic, Silicate, Silicone

In the assortment of plasters for the facade there are also modern solutions. These are silicate, polymer and silicone plasters. These types of finishing materials give the facade greater resistance to water, create a dirt-repellent film on the wall surface, and prevent cracking.

Although they are called "plaster", but in essence - the finishing thin-layer coatings related to decorative. These are various types of pebbled plasters creating a surface like “bark beetle”, “fur coat” and others. They are applied to the prepared base - the surface of the walls, which is leveled using conventional cement-sand mixtures or sheathing with TsSP sheets. Polymer facade materials appeared relatively recently. But decorative coatings with the texture of "fur coat" or "bark beetle", as well as many other options, decorated the walls of houses much earlier. In the traditional technology for applying textured plasters, the foundation is first made - the unevenness of the wall is smoothed out and the required layer is created with cement-sand mortar. First they make a spray - they throw a liquid plaster mortar on the wall and let it dry. Its task is to penetrate into the seams and cracks, behind a tussle or mesh and create good adhesion to the wall. Then a hint follows - apply a layer of plaster, align it with beacons as a rule and compact it with a trowel. The last layer is a coating. It is applied to the already grasped, but not completely dried up soil (hint). The coating layer has a thickness of 2-4 mm. It is applied with a creamy consistency prepared in fine sand. Often, lime coatings are used for nakryvki as more plastic. After setting, the surface is gently rubbed with a trowel or a trowel. Carefully made grouting of the last layer creates a smooth surface, resistant to water and ready for painting. When creating a decorative coating, the last layer of plaster (nakryvka) is replaced by applying a texture. The texture of the "fur coat" is sprayed: with a brush, a broom or a special plaster bucket - hopper. The hopper can be manual (with a drum in the form of a hard brush) or connected to the compressor. Dyes and stone chips are added to the plaster mortar for the textured layer. A similar texture can be obtained by rolling a fresh coating layer with a roller. If you slightly smooth the resulting irregularities with a smoothing iron, then the result will be a “smoothed coat”. The bark beetle texture is obtained if fine gravel or coarse-grained sand is added to the liquid plaster mortar for covering - the pebbles leave burrs similar to those consumed by a bug. On plastic plaster, you can create various patterns and textures with a spatula, embossed rollers, dies and other tools. After setting, the masonry contours are applied to the surface of the plaster composition, seams or rusts are cut. After the final hardening, the surface of the “stones” is machined mechanically - by a trojan, buchard or scarpel, depending on the required texture. In addition to applying decorative textured plaster over the entire area of the wall, the facade can be decorated with architectural elements - breaks (cornices, moldings, pilasters), also made of cement-sand and lime mortars. Profiles of rods, cornices, frames of windows and arches are “pulled” by specially made spatulas-templates. Stucco facade - an excellent option for decorating the walls of the house. From a variety of methods, you can choose a surface design for any style - from rustic to classic. Plaster will become an equal partner or background for other types of facade decoration. About what materials are used for facing, read in the publication of our site. Facade decoration: brick, tile or stone - what to choose? You may also be interested to learn about unusual finishes. About this - in the article Facing the house: 6 original and inexpensive ways.

Textured facade plaster “smooth coat”Stucco: solid, reliable and beautiful

A plaster coat is created before applying the textured finish.

The surface of the applied stucco is leveled by the rule

Grouting

"Fur coat" made of plaster on the facade

Trowel plaster pattern

You can also simulate a stone surface. To do this, use terrazite plasters - lime mortars with a filler of stone chips (up to 10% solution).

Imitation of stone on the base. Photo from myshtukaturka.ru

Architectural elements - breaks, can be done with plaster