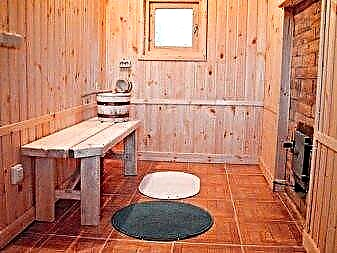

The most common material in the construction and decoration of the bath is, of course, natural wood. It is also undeniable that one of the finishing materials that complement the wood as well as possible is ceramic tile. Like any building material, it has its own advantages and disadvantages.

Slip resistance

One of the most important criteria when choosing a tile is the type of coating: glossy or matte. The best option for laying on the floor is the use of matte tiles. The reason is simple and obvious - its friction coefficient (or slip resistance) is much higher (R11-R13) than matte (R9-R10). Consequently, the surface of the matte tile does not allow sliding, which is important in conditions of high humidity, which are characteristic of almost all rooms of the bathhouse. But this is of particular relevance, first of all, for the washing room and steam room, where the humidity is the highest. In addition, it should be borne in mind that people move around these rooms without shoes, barefoot, which further increases the risk of slipping.

By the number of profiles on the tile

Another indicator for designating non-slip tiles for the floor of the bath, taking into account the ratio of the area of one profile against sliding to the total area of the element. It is marked as “Vx”, where instead of x the value obtained is substituted in cm3 / dm3. The first class of non-slip tiles is denoted by V4 and has the indicated ratio of 4 cm3 / dm2, and the very last - V10 (respectively, 10 cm3 / dm3).

Water absorption and wear resistance

For obvious reasons, the rate of water absorption should be minimal, and the rate of wear should be maximum, namely, for floor tiles, which guarantees a long term of operation without the need for repair or replacement. Tiles with such characteristics are usually marked with the designations AI and BI (where A indicates the production by extrusion, B - by pressing, and I- shows minimal water absorption). Another property of this tile is that it is difficult to cut due to its higher density.

Frost resistance

It becomes relevant for irregular use of the bath, when during operation there is strong heating, and the rest of the time the room is not heated. In this case, the tile coating must necessarily have increased frost resistance, otherwise it will quickly become worthless.

Quality and appearance

The least formal, but no less important criterion on which the most complete satisfaction depends on visiting a bathhouse.

As a conclusion, you can summarize and group the characteristics necessary to ensure that the tile floor is high-quality, durable, and most importantly, convenient and extremely safe to use:

- rough surface

- increased wear resistance

- reduced moisture resistance

- beautiful appearance.

All the necessary characteristics are contained and indicated on the packaging of the purchased ceramic tiles, which must be carefully studied and checked that the qualities match the future use.

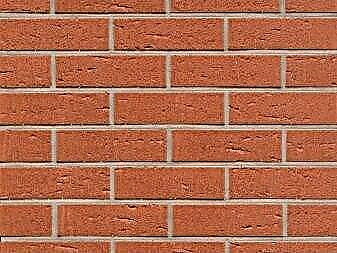

Brick

It is made from different grades of clay, which is burned in industrial furnaces. Benefits:

- high strength

- resistance to prolonged exposure to moisture,

- chemical immunity

- easy cleaning from pollution.

Thickness - 8-12 mm.

Terracotta

Used for wall cladding. It is not recommended to apply to the floor, since the tile quickly loses its original appearance due to the fact that dirt is clogged in the pores of the material. It is not glazed during production.

Therefore, it looks as natural as possible. Outwardly resembles natural stone or brick. Benefits:

- high strength

- resistance to moisture, chemicals, high temperatures.

Talkhloritic

It is used for facing floors, walls in baths. Benefits:

- long heat retention,

- high strength

- resistance to temperature extremes,

- maintaining shape when exposed to moisture.

Talkochlorite tiles have one significant drawback - the high price.

Ceramic

It can be made using extrusion or extrusion method. Raw materials are clay, which is burned in industrial furnaces. Benefits:

- high strength

- resistance to temperature extremes, moisture, chemicals.

- durability, wear resistance.

There are no serious flaws.

Classification by shape and size

Three types are distinguished depending on the form:

- square.

- rectangular.

- decorative different shapes.

The first two options are most relevant for beginners who are first engaged in masonry.

The first two options are most relevant for beginners who are first engaged in masonry.

Dimensions can be found in a special table.

Requirements

To choose the right tile flooring for the bath complex, you need to study the requirements for the material:

- The tile must have a rough surface in order to have an anti-slip effect.

- For the material to last longer, absorb less moisture, its back side should have low porosity.

- It is better to choose a double firing tile. It is more durable, strong.

- The more complex the surface of the base, the smaller the size of the tile should be. This recommendation will simplify installation work, there will be less undercut.

Selection principles

When choosing a tile coating you need:

- Choose the material with the lowest moisture absorption.

- Carefully inspect the tile for visual defects - cracks, chips, scuffs.

- Find on the packaging what the material is intended for - cladding of floors, walls or stoves.

- Pay attention to the level of wear resistance. It can be identified by marking. It should be the highest of all possible options.

Also pay attention to appearance, texture. This choice depends on the wishes of the owner of the bath.

Advantages and disadvantages

- Durability, wear resistance in comparison with wooden floorings.

- Ceramic surfaces are easy to clean.

- Resistance to temperature changes, moisture, chemicals.

- Mold does not form on the surfaces, fungus.

- Attractive look.

- During installation, you can easily arrange the angle of water discharge in the right direction.

- You can install a system of "warm floor".

Disadvantages:

- High price compared to wood.

- The occurrence of difficulties when laying tiles of complex shape.

- Cold base.

If you install a "warm floor" system, you can get rid of the last drawback.

Marking

When choosing, you need to pay attention to the labeling. Decoding of the main designations:

- Capital letter T - high heat resistance.

- Letter R - texture (matte or glossy). Numbers are indicated next to the letter. The larger the number, the less slippery the material will be.

- PEI designation - abrasion resistance. A number is indicated next to it. 1 - can be used in the bathroom, bathtub, 2 - suitable for dressing rooms, corridors, 3 - for any bath rooms, 4 and 5 - industrial stoves.

- Sun icon - resistance to temperature extremes.

- Snowflake icon - resistance to low temperatures.

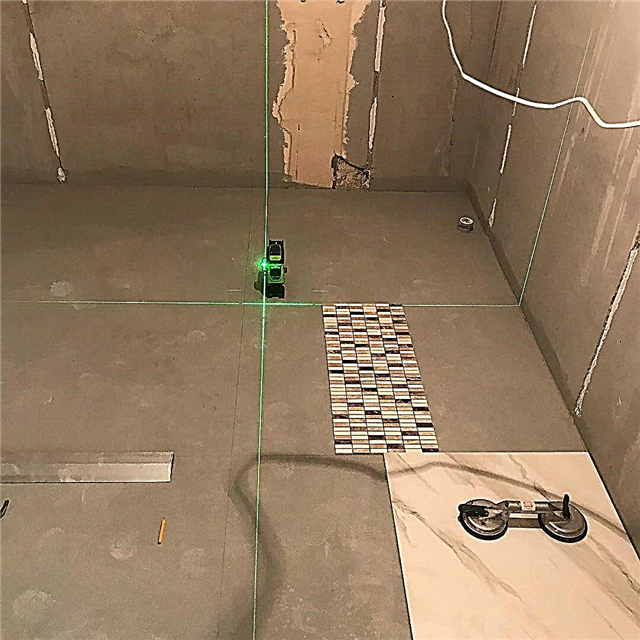

Mounting

Not everyone knows how to put tiles in a bathhouse on the floor, but this is a simple process. It is enough to properly prepare the foundation, get acquainted with the stages of the work in theory. Before starting work, you need to practice on rough sections of the floor.

Adhesive and grout selection

When choosing tile glue, you need to pay attention to two parameters:

To mix the dry composition you will need an empty container, a drill with a mixer nozzle.

Grout is needed so that water does not get under the coating, and the seams turn out beautiful. You need to buy a composition that is suitable for the selected glue. In addition to this, it must be resistant to temperature extremes, freezing, moisture.

Tool preparation

Before starting work, you need to prepare:

- mixer drill,

- two spatulas (large and small),

- comb spatula

- building level,

- crosses for seams.

In addition, you will need a grinder with a disk for a stone or a special tile cutter.

Concrete

Concrete foundation is considered the best when it comes to cleaning facilities. By adding special additives to the dry mixture during the mixing of the solution, it is possible to obtain a waterproof mass.

The concrete base resembles a layered cake of several layers:

- Sand pillow with crushed stone.

- Concrete (7 cm).

- Thermal insulation. Expanded clay or mineral wool can be used.

- Reinforcing mesh.

- Concrete layer up to 10 cm thick.

- Waterproofing.

Wooden

Before starting to prepare a wooden base, you need to dismantle the old flooring, replace it with a new one. Boards must be solid, free of mold or mildew. There are three options for preparing wooden substrates:

Before starting to prepare a wooden base, you need to dismantle the old flooring, replace it with a new one. Boards must be solid, free of mold or mildew. There are three options for preparing wooden substrates:

- A concrete screed with a thickness of 3 cm is made on top of the wood base. A damper gap of 1-2 cm thick is left along the walls. A layer of insulation is placed on the wall to a height of 15 cm, fixed with a construction stapler. Concrete is poured only over the reinforcing mesh.

- Dry method. On top of the old wooden flooring, plywood, OSB or GKLV sheets are fixed. Using a special sealant, the joints are filled and ground to obtain a smooth surface.

- Several layers of GKLV are glued to the board flooring. It is recommended to use a special polyurethane adhesive.

Drain arrangement

To protect the washing from accumulating moisture, the flooring should be arranged with an angle to one side. The location of the drain should have been chosen at the stages of construction of the base. Through a concrete "pie" is a plastic pipe that goes outside the building. At the place of discharge, you need to install a metal or plastic grate to hold large debris, protect your feet from falling into the pipe.

Hydro and thermal insulation

The quality of thermal and waterproofing depends on the level of comfort in the bathhouse. There are two popular ways to waterproof a base:

The quality of thermal and waterproofing depends on the level of comfort in the bathhouse. There are two popular ways to waterproof a base:

- Bitumen - using a roller or a dense brush, a liquid layer of bitumen is applied to the prepared surface. After this, you need to wait until the composition hardens with a layer.

- The lay method. On top of the prepared surfaces, a sheet material, for example, roofing material, is laid out.

A less popular option is penetrating waterproofing. These are special compositions that are applied to concrete. This method is free from disadvantages.

Mineral wool or expanded clay is more often used as thermal insulation.

Grout

Features of grouting:

- You need to start grouting a day after masonry. It is important to let the glue harden before it can be walked on.

- Grout must be applied with a special rubber spatula, passing through each seam.

- 15 minutes after filling the seams, wipe off the remains of the fugue with a damp sponge.

A few hours after the jointing, white stains may appear on the floor surface. They can be wiped off with a damp cloth and detergents.

Care Tips

It’s easy to care for the coating. So that the seams do not darken, it is recommended to cover the puffer with a special water-repellent composition. If contaminants appear, they can be easily removed with a damp cloth; if this is not enough, detergents can be used.

In saunas, you can see less and less wooden floors. This is due to their weaknesses. The most relevant option is a tile floor. It is durable, strong, does not collapse under the influence of moisture.

Features

Bathrooms are exposed to steam, water and temperature extremes. The traditional finishing material for the steam room is wood, but lately ceramic tiles have been increasingly preferred. The ceramic product is durable, does not require special care, is not afraid of water and high temperature, resistant to chemical and mechanical effects. Ceramic tiles are made of clay and mineral additives, which gives it another important quality - environmental friendliness.

When heated, this material does not emit harmful substances, so it will not harm the body.

How to choose?

The flooring in the bath should have a number of certain qualities, which are important to consider when choosing a finishing material. When choosing, you should pay attention to several factors:

- Moisture resistance. When choosing a tile on the floor in a bath, first of all, you need to pay attention to the degree of moisture resistance of the material. This indicator directly depends on the technology of manufacturing tiles and the quality of the raw materials used. If the tile was double fired, it will be more porous and less dense.

- Wear resistance. There are five classes of wear resistance - PEI1 – PEI5. The higher the class, the greater the load the product can withstand. The material for facing the bath rooms should be quite wear-resistant. For such a room, floor tiles of the PEI2 – PEI3 group are suitable. The thickness of the ceramic plate for the floor can vary from 7 to 11 mm.

- Heat resistance. The coating of the furnace and the walls adjacent to it should have high heat resistance. When marking such products are marked with the letter "T". A snowflake on the packaging means that the material is resistant to frost. Frost resistance depends on the degree of moisture absorption - the less moisture the material absorbs, the better it will tolerate the temperature with a minus sign. The combination of the snowflake and sun icon on the packaging indicates that the tile has high resistance to temperature extremes. This indicator is important if in the winter time the steam room will not be heated.

- Relief. For the floor in the bath, you should choose a tile with a relief or rough surface, which will provide reliable grip with the foot and eliminate the likelihood of falling on a slippery floor.

It is recommended that you opt for tiles marked R11 – R13, as this is the highest anti-slip coefficient.

- Security. Tiles should not emit harmful substances when heated.

- Quality. An equally important aspect to consider when choosing a floor covering in a bathhouse or sauna is the quality of the tile. It can be defined visually. A good tile has a flat, smooth surface without chips and cracks, a flat edge and a uniform color. It is worth attaching two tiles with the wrong side to each other, for a high-quality product, the angles and sides coincide.

There are quite a few varieties of tiles, it is worth considering in more detail the most popular options.

- Ceramic tile (tile) - This is the most famous type of tile. The production technology consists in the formation of a plate (a mixture of clay, sand and various mineral additives), firing and coating with glaze.

- Brick tile It is made from certain grades of clay with the mixing of coloring substances. It is fired once at a temperature of +1200 to + 1450 ° C. This tile is heat-resistant, durable and resistant to sudden changes in temperature, so it can be used for facing the stove and flooring in the wash.

- Terracotta tile has a wide range of applications. The main material for the manufacture of this type of tile is white kaolin clay. It does not contain impurities and other additives. A manufacturing feature is long-term (sometimes over 18 hours) firing at extremely high temperatures. This type of ceramic product is highly resistant to heat.

- Porcelain Tiles. The basis for its manufacture is clay, which added crushed rocks - quartz and spar. The tile is fired under pressure at a temperature of more than + 1250 ° C. The product is durable, finely porous and practically does not absorb moisture, which makes this type of tile suitable for facing the bath.

- Talc Chlorite Product. This type of cladding is characterized by high resistance to temperature jumps, moisture resistance and low slip coefficient.

Depending on the manufacturing method, tiles can be of the following classes:

- A - manufacturing by extrusion. The pasty mass is extruded through a special mold, then cut into fragments,

- B - pressing. The powdery mass can be pressed under high pressure.

The following types of tiles are not suitable for use in bath rooms:

- porcelain stoneware is undesirable for flooring in rooms with high humidity, since it has a smooth surface,

- it is better not to use glazed tiles near the stove or stove. From exposure to extremely high temperatures over time, such a product will crack and become unusable.

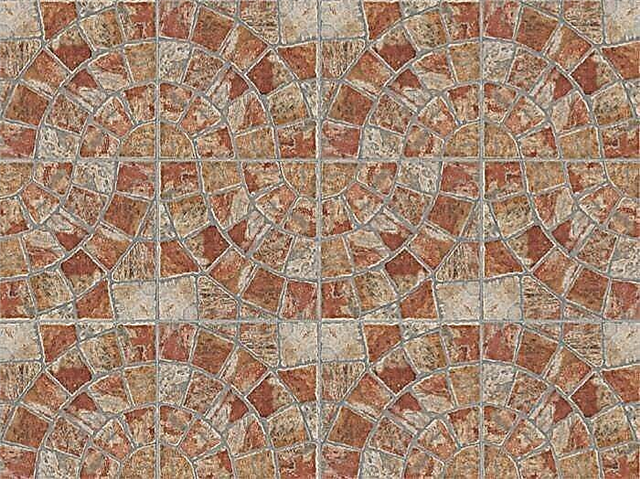

Design

A major role in the choice of finishing materials is played by such concepts as color, pattern, texture, size.

- Under natural materials. Tile imitating wooden boards or natural stone is very popular. The ceramic “stone” has a matte embossed surface, which makes it non-slip.

- Floral design. It is not necessary to finish the whole room with a tile with a floral pattern. It is better to use this design in part, highlighting the accents.

- Geometric ornament. Such a tile design is suitable for placement in a restrained laconic style, which will make it boring and give originality.

- Oriental patterns. A floor decorated in this style will become the stylistic center of the room. You can complement it with calm colors and discreet details.

Skillfully using the design and size of the tiles, you can create a unique style, give the room a highlight and visually make it bigger.

At the peak of popularity, light natural shades, the simplicity of the lines. The use of ceramic products of non-standard shapes, a variety of textures and their combination will help to make such a design boring.

How to lay?

Putting a tile in the bathhouse with your own hands is quite realistic if you treat this process with due attention and carefully study all the nuances. The result and reward for the work done will be high-quality and beautiful decoration of the room, which will last for many years. Since the floor in the room is most susceptible to mechanical stress, the installation process must be approached with great accuracy. First of all, the following tools and materials necessary for installation work should be prepared:

- rubber mallet

- trowel with teeth

- calibration crosses

- glass cutter or tile cutter,

- mixer and container for mixing the adhesive solution,

- building level,

- pencil, roller, scraper.

Foundation preparation

Before facing works, the underground is being prepared and waterproofing works. It is necessary to make a kind of cake from different layers, which will serve as protection against moisture and temperature changes, namely:

- the surface should be cleaned of debris and dust,

- wooden logs should be checked for strength, leaking areas should be replaced, after which the entire surface should be treated with an antiseptic solution,

- in order to protect the wood from moisture, it is necessary to carry out waterproofing work, for example, treated with latex impregnation. For greater waterproofing, roofing material or roofing can be laid on top,

- then do a screed. It is performed with a bias towards the drain hole,

- as soon as the floor dries, it can be primed.

An alternative for such a foundation can be a concrete floor on which a layer of tile is laid.

Tile Preparation

In the case of laying ceramic tiles on a cement mortar, it is recommended to soak the products in water before starting work. After soaking, the tile does not absorb moisture from the solution so intensively, which contributes to longer mobility and better adhesion to the surface. In cases where a modern adhesive mixture is used for laying, soaking is not necessary, since high-quality adhesive from leading manufacturers of building materials has high adhesion properties.

Stacking

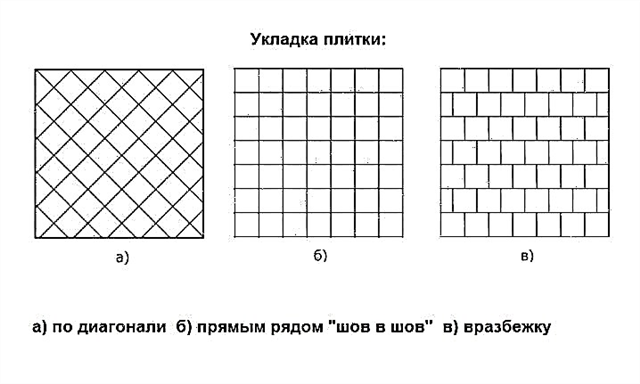

The choice of glue should be taken seriously, given the features of the room. For laying tiles in a bath or sauna, you should choose a moisture-resistant adhesive mixture with good adhesion. There are three options for laying tiles, such as:

Start laying tiles from the far corner. If to carry out laying from the center of the wall, then first you need to mark the middle and begin to lay out the tiles on both sides of the marked line. If the drain hole is in the center, then it is better to start laying tiles from this place. Glue solution should be applied to the underside of the tile and directly to the floor. The tile is lightly pressed and tapped with a rubber mallet to set to the desired level.

So that the gaps between the tiles are the same, special calibration crosses are used, which are removed after the adhesive solution dries. In the end, you need to revet the remaining places with tiles, trimmed to the desired size. Excess fresh cement mortar is easily wiped off the tile with a damp cloth until it is frozen.

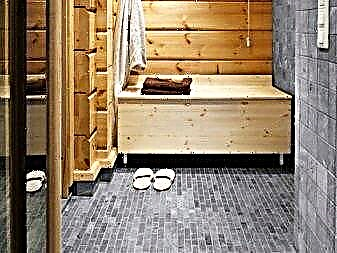

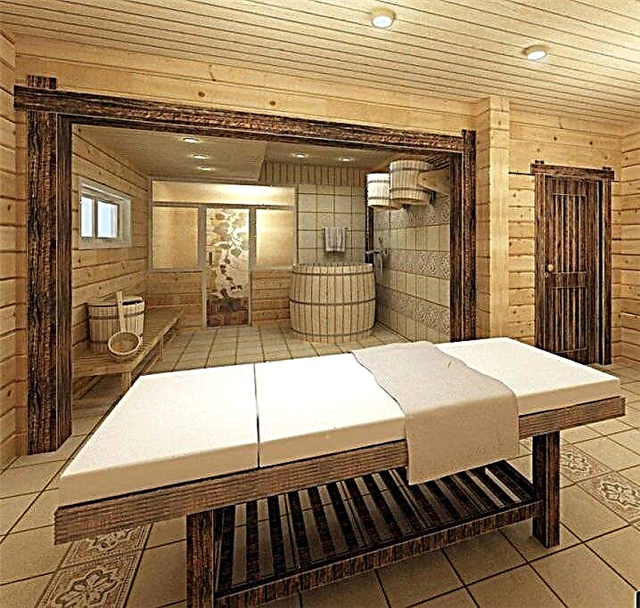

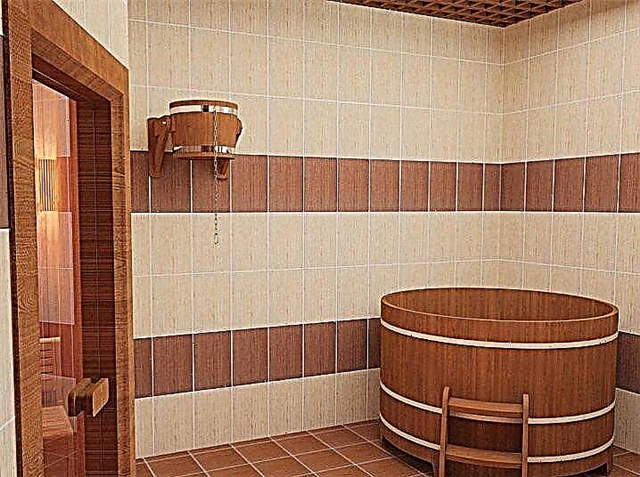

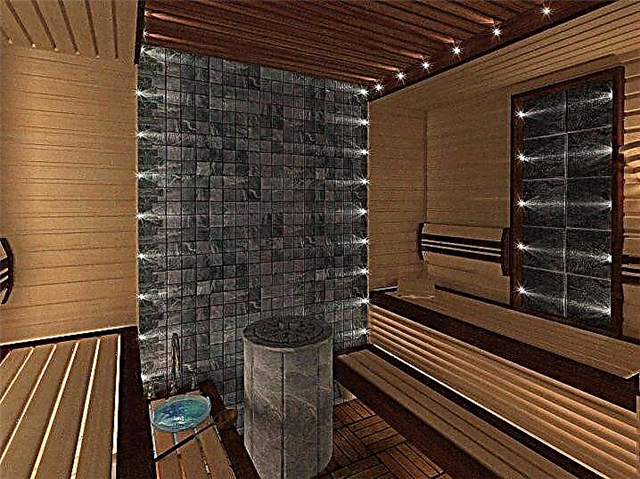

Beautiful examples in the interior

Properly selected tiles on the floor in the bath should be embossed, which will ensure safety when using the bath room.

Ceramic tiles of natural shades will make the bath room cozy.

Ceramic tiles blend well with wood finishes.

A skillful combination of facing materials plays an important role in the interior design of bath rooms.

See how to lay tiles in the bath in the next video.

Cladding selection

Many modern tile manufacturers offer collections to create a durable non-slip floor covering for a bath or sauna. In order not to get confused in the proposed variety, but to choose the right version of tile on the floor, several points should be noted.

- Moisture absorption level. It is better to purchase a tile with a minimum rate of moisture absorption, since it will often come in contact with water. The porosity of the tile is an important indicator, since it affects the absorption of the tile. This criterion depends on the composition of the clay and the manufacturing method. Tiles marked AI and BI are suitable for flooring in the bathhouse. The letter “A” indicates that the tile was made using an extrusion method (a molding machine extrudes a pasty mass). The letter "B" means the pressing method (a press is used to form the tiles).

It is also worth paying attention to the choice of glue, since it must be moisture resistant and reliable.

- Wear resistance. This indicator depends on the labeling. For a bath you need to purchase tiles with a high level of wear resistance.

- Quality. To determine the quality of the tile, you should carefully look at its appearance. It should have the correct shape and even angles. You should take two tiles and fold them to each other with the front side so that they fit snugly against each other, while the corners should match. This indicates excellent product quality.

- Design. When choosing tiles, design plays an important role, because texture, color and print will help to decorate the room, create a cozy interior.

- Destination. Tiles for flooring must be resistant to mechanical stress, and withstand increased traffic.

Ceramics

Modern ceramic manufacturers offer a wide range of products. To make a high-quality and durable floor in the washing room or in other rooms of the bathhouse, The following criteria should be noted:

- The surface of the ceramics should be such as to exclude the possibility of slipping if you walk on it with bare feet. It is worth choosing tile rough or corrugated.

- The moisture absorption coefficient should be more than 10 percent. The most effective is ceramic granite with a coefficient of 3.2 to 3.8 percent.

- Tile strength should be at a high level. Ceramoranite is an excellent choice as it is made using double firing technology.

- To create a floor in the bath, it is better to buy a small tile. An excellent format will be 10x10 cm. This will create the necessary slope for draining the water.

Thermal tile

Heat-resistant tile is a common material for creating floor coverings in a bath, since the main feature is that it is able to withstand high temperatures and provides fire safety.

Heat-resistant tiles for use in the bathhouse on the floor should be high-strength, environmentally friendly. It should provide good heat transfer and have a good indicator of heat resistance.

When choosing, you need to pay attention to resistance to mechanical damage. It should have a low porous base, since this option prevents its expansion at high temperatures. Thermal tile is characterized by increased thickness when compared with its analogues.

Decking modules

Decking models are in great demand today to create a durable and stylish flooring in the bathhouse. Tiled modules allow you to create a moisture resistant and hard flooring. In appearance, they resemble a parquet board.

For a bath, it is worth choosing decking modules from strong tree species. They must be distinguished by a corrugated surface to exclude the possibility of falling.

Styling tips

Experts recommend that you follow some rules in order to properly lay ceramic:

- Laying non-slip tiles can be done in different ways: diagonally, inversely or seam into the seam. It is suitable for concrete or wooden floor.

- It is necessary to pre-stick plinth tiles, while using wall fastening.

- When laying ceramics, you should adhere to the bias, especially in the washing compartment. When calculating the slope, it is worth using a ratio of 1: 100. It should be carried out in the direction of the drain, so the water will not stagnate on the floor.

- To lay the tile evenly, you need to use a rail or lacing. She will help to carry out visual control.

- When laying mastic or adhesive cement mortar should be applied to each tile.

- The floor surface must also be treated with adhesive, and then leveled with a notched trowel. To create the necessary horizon, a building level and a rubber mallet are used.

- After laying, remove excess adhesive with a spatula.

- To control the size of the connecting joints, you must use special crosses.

- Laying tiles on the floor requires the use of a seam. Its thickness can vary from 2 to 4 millimeters. Depending on the desired seam width, you need to select the size of the crosses.

- Tile trimming can be done using a tile cutter. Tiles that can be trimmed should be used in inconspicuous places.

See how to properly lay tiles on the floor in the bath in the next video.