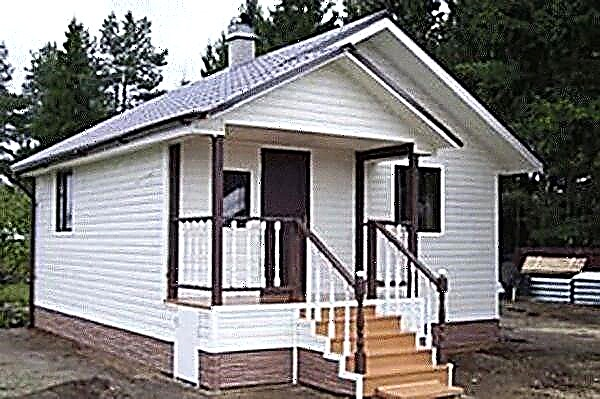

Siding is popular not only because of aesthetic appeal and accuracy, but also due to its strength, ease of installation and reasonable price.

Siding is popular not only because of aesthetic appeal and accuracy, but also due to its strength, ease of installation and reasonable price.

The range of materials allows you to choose the right panels for color, material and texture.

They can be made of various materials: wood, metal, PVC.

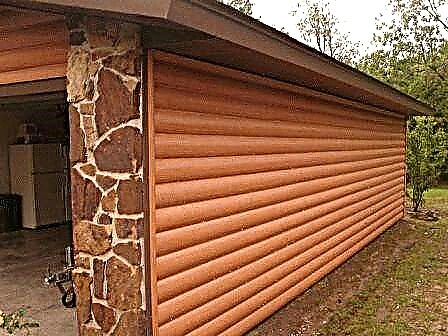

Metal panels can be made in the form of imitation of natural wood. They are called - "under the tree."

Wood siding: pros and cons

Metal siding must meet the requirements of GOST, and since the panels are quite heavy, their installation must be done on a reinforced crate. Due to the positive performance of metal siding, it occupies one of the leading places among the range of panel types of cladding.

Advantages

Advantages of metal siding:

- durability (operational properties are stored for more than fifty years),

- strength,

- polymer coating stability (color),

- low rate of thermal expansion,

- is not a medium for the spread of fungi and mold,

- fire safety

- wide range of color solutions,

- convenient fastening of sheets,

- ease of care

- operational characteristics maintain a wide range of temperatures (from -80 ° C to + 60 ° C),

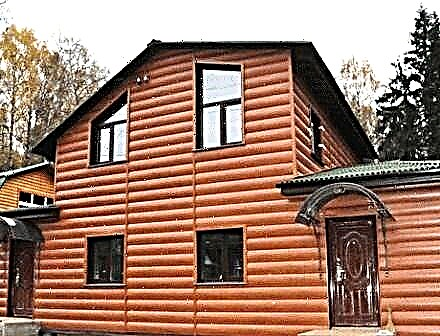

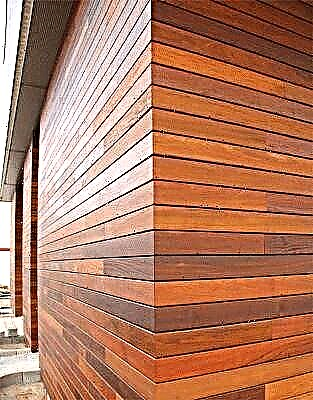

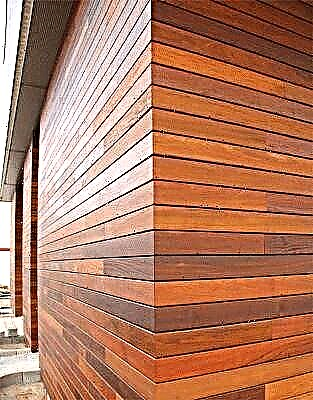

Wood imitation has an attractive aesthetic appearance and creates an atmosphere of natural unity.. Among the trees, such a house will fit perfectly into the overall picture.

House with a metal siding under a tree

Disadvantages

Some disadvantages should be considered.:

- the cost of metal sheets exceeds analogues of vinyl,

- when exposed to the sun, metal siding is very hot, which can contribute to increased temperature in the building,

- high rate of thermal conductivity (metal siding is most often recommended to be mounted on an external insulation),

- with a large weight of the structure of metal panels, reinforcement of the foundation and load-bearing walls is required.

Install in such a way as to protect the panels from pressure or mechanical impact..

The main advantages of other types of siding

Wooden houses are always popular, look noble and expensive. Due to the fact that the natural material (wood / board) requires some care, is short-lived and significantly susceptible to the effects of the fungus, it is not always suitable for construction.

Metal siding is divided into the following types:

Constructed houses made of concrete or brick are sheathed with wood siding to give them a natural look. Such a house does not look like a monotonous urban structure: a tree (even if it is an imitation) gives a feeling of warmth and comfort. The most popular types of metal siding are “oak”, “dark wood”, pine. ”

Wood siding does not fade, unlike PVC panels, which, despite modern technology, fade over time.

Metal panels are more durable, they are resistant to weathering. Metal does not burn unlike other types of panels that can melt or burn.

If you characterize the material in the external aspect, then it’s almost impossible to distinguish wood facing from natural.

Specifications

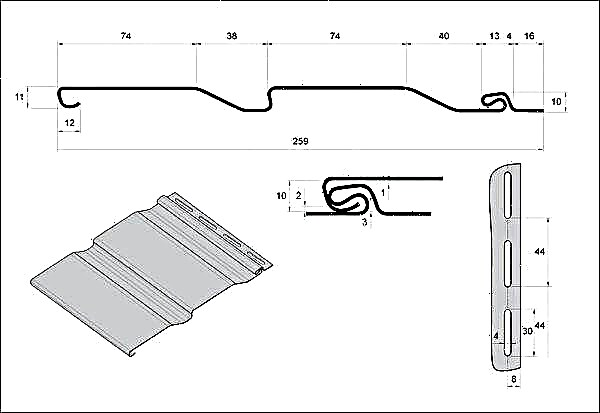

The characteristics of metal siding in technical terms may vary slightly: each manufacturer has its own specifics for the production of these sheets, but in general they must comply with the parameters established by GOST.

Sheet Metal Requirements:

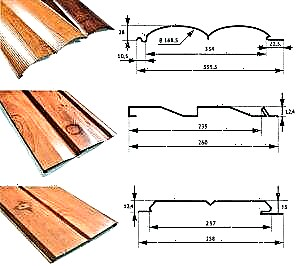

- metal siding sheet should be long from 500 mm to 6000 mm,

- sheet width - 225 mm, 325 mm, 325 mm,

- panel thickness differs from different manufacturers: from 0.4 mm to 0.9 mm,

- the mass of one sheet depends on its length and is in weight from 5 kg.

The assembly area of metal siding is different from the area of the facade.

This is due to the fact that the area of the mounting panels includes latch locks, which during installation overlap each other.

Equipment

Additional elements are used to secure the end of unprotected parts, window and door openings, corners, joints, complete the entire structure of the coating.

The set of metal panels includes elements:

- outer corner (complex and simple),

- internal angle (complex and simple),

- connecting strip (complex and simple),

- sloping rail

- strips of external and internal corners (upper, lower),

- molding,

- clypeus,

- starting bar

- plinth base

- drainage.

Elements for panels need to be purchased from the same manufacturer, so they will ideally fit in size, color, and there will be no difficulties during installation.

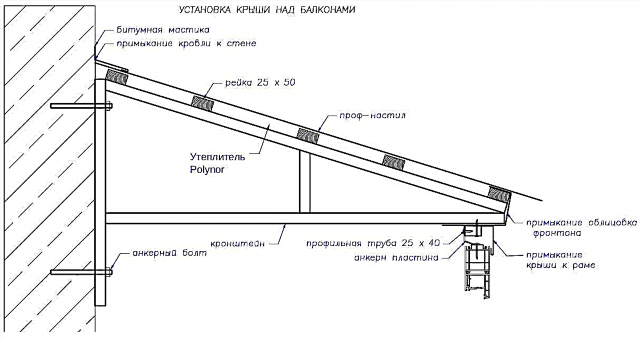

Preparation of the crate and wall insulation

It is advisable to install a metal profile crate under the metal cladding: it does not require processing, can withstand the load and is lightweight at the same time. It can be made of wood, but the bars should be pre-dried, treated with antiseptic agents.

Recommended crate pitch - 30 cm. This arrangement of the rails is the same for both horizontal and vertical mounting. In the openings of windows and doors, mount rails.

When laying the insulation, attention should be paid to the following points:

- the material should fit snugly against the wall, and there should be no gaps between the guides and the insulation,

- there should be no gaps in the joints of the material,

- when attaching the insulation, you should choose the length of the dowels 50 mm longer than the thickness of the insulation layer.

Installation of insulation should be carried out in accordance with the recommendations for the type of material.

Setting the start bar (start bar)

The start plate is the first installed part when performing work on facing with metal siding.

Before mounting the start plate, it is necessary to determine its location. Using the level, stepping 30-40 cm from the lower horizontal point of the house, you should draw a line along the length of the wall.

Horizontal location

Along the marked line with the upper edge fasten the bar along the entire length. Siding sheets are inserted into the plank and fastened to the crate guides.. There is no need to make a gap between the strips, since the coefficient of expansion of the material is too small. A small gap is most often made for the convenience and safety of installation.

Vertical layout

If you want to mount the siding in a vertical way, then in addition to the initial bar, you also attach angular, mounting and sloping bars. The pitch of the starting bar should be 300 mm.

Setting the start bar

The device is obtuse and sharp corners

Due to the fact that metal corners have the flexibility to compress (expand), their degree can be easily changed by compressing the corner bar and pressing on it. So, for an obtuse angle, pressure is applied to the central part of the angle (to expand the profile angle), for an acute angle, on the sides (to reduce the profile angle).

Setting obtuse angles

Installation of vertical strips - angles and H-shaped connector

After the metal sheets of the cladding are installed, corners should be fastened.

Wide siding angles. They should overlap the panel by about 10 mm., While the panel should not rest firmly against the corner: a slight indentation is required.

The length of the corner profiles is 300 cm.

Before setting the corners, note the indent from the top edge for spotlights.

The corner profile is laid to the corner of the building and fastened with screws, starting from the bottom. The bar should not reach the ground by 6 mm.

If the profile is shorter than the height of the corner, then the corner profiles overlap each other with an overlap of 2.5 cm (upper - on the lower), so that the upper profile is trimmed, then the docking of the fastening parts of the strips will have a gap of 9 mm.

Joining of all corners of the facade should be done at the same level..

Sometimes, in order to save money, two starting profiles are used to join the corners, but in this case, waterproofing the wall surface under the profile is required, since the tightness in this case is weak.

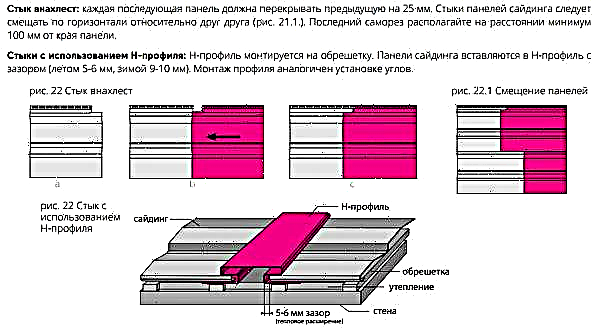

Install H-Connector

H-shaped connectors serve to join two siding strips. The fastening of such profiles is carried out similarly to corner strips. So, the upper part is adjusted taking into account the clearance for the cornice (3 mm), the lower part of the profile falls below the starting strip by 6 mm.

First, the profile is fastened with screws on top so that it moves freely, then its vertical position is checked and tight fastening by other self-tapping screws is made.

When mounting an H-shaped connection, the starter bar should be brought out so that it is adjacent to this profile.

If the panels are overlapped, the use of such a connector is not required.

Install H-Connector

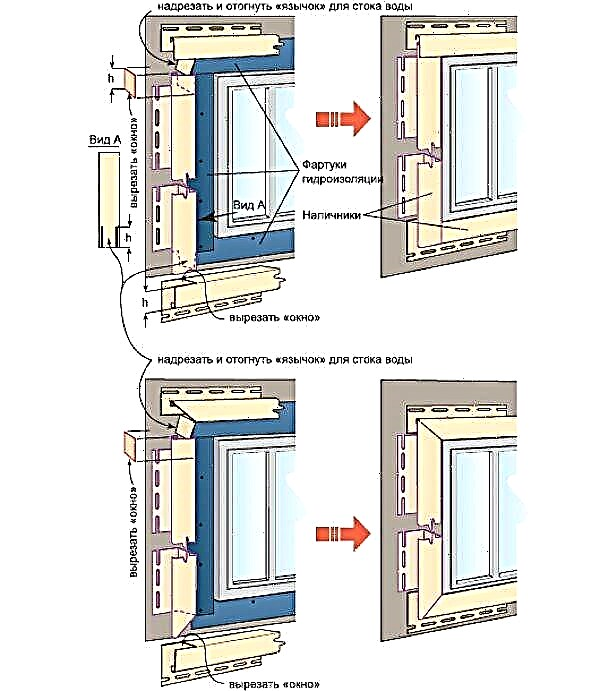

How to get around siding windows and doorways

Window openings and door frames are framed using a J-profile or window sill.

The essence of the work varies slightly depending on the depth of the opening (more or less than 20 cm).

When opening a window less than 20 cm, a J-profile is used (its length can be 22 cm). Overlapping the window opening occurs by overlapping the slats. On the plane of the frame, a finishing strip is mounted in which a J-profile is inserted.

You can mount the slats at right angles: cuts are made on the vertical parts, and cuts with the technology of bending the material inward are made on adjacent parts. The framing is made decorative by the installation of adjacent elements at an angle of 45 ° by means of a gash.

If the opening is more than 20 cm, the J-profile is replaced with a corner strip or cut siding stripes.

When siding is performed near a window opening, a horizontal cut is made from the lower edge of it in the nearest siding sheetequal to the length of the opening, taking into account the allowance for the temperature seam.

The cut out place should fit easily into the landing profile. Holes for fasteners are made in the cut-out panel. Mounted tide as a window sill, taking into account temperature gaps.

Similarly, sheathing of doorways.

Installation of window openings

Installation of finishing strips

The finishing strip serves to hide the edges of the sheets, creating aesthetics to the side joints. This strip is mounted across the trim under the eaves of the roof. Such a bar can be used for window openings. Another finish strip is used when changing the direction of the cladding from longitudinal to transverse.

Fasten the finishing strip should be tight to the edge of the wall with screws. Installation is done before installing the last sheet of siding. Further, the panel is cut out in width, perforation is done in the edged part and the panel is connected to the previous siding row, and its upper part is bent under the finish bar.

Thus, a metal siding under a tree has good characteristics and a decorative component. Its installation is carried out without special skills, and the quality of the lining is complemented by components that can not be dispensed with.

Installation of finishing strips

Material Description

Strips of metal siding are produced in lengths from 5 to 6 meters, the width of the panel can be 225 or 325 mm. The thickness of the material varies depending on the manufacturer and is in the range of 0.4-0.9 mm. The weight of one strip varies, depending on the thickness, width and length, the approximate mass is 5.5 kg.

Strips of metal siding are produced in lengths from 5 to 6 meters, the width of the panel can be 225 or 325 mm. The thickness of the material varies depending on the manufacturer and is in the range of 0.4-0.9 mm. The weight of one strip varies, depending on the thickness, width and length, the approximate mass is 5.5 kg.

When calculating the needs of the material for covering the facade, pay attention to the fact that when assembled, the panel width will be slightly narrower due to the longitudinal latches-lockswhich in the mounting position are hidden under the surface of the next strip. The disadvantage of the material is that after bending or hitting such panels do not straighten to their original position, unlike, for example, plastic.

Depending on the material used for the base, the products are divided into steel, copper and aluminum panels. They differ from vinyl in cost, for example, steel and aluminum have almost the same cost (the difference is about 10%), but both materials are 2–2.4 times more expensive than vinyl siding.

Steel based material

Steel siding under the tree is durable and its strength is more than aluminum, it is used for administrative and public buildings, it is hardy, reliable and durable material, such qualities pay back the increased cost. Due to the considerable weight it is used on the facade only in those places where there is a constant danger of mechanical damage.

Thanks to the zinc layer in the composition of the "cake", the material is highly resistant to corrosion and atmospheric damage. Due to the polymer film, the color and texture of the tree is widely used and attracts attention with a respectable appearance.

Aluminum siding

The weight of the material is much lighter than steel, but strength loses. Due to its elegant appearance and lightness, it is used in decorating the walls of cottages and private housing construction (in buildings where there is no high traffic and the possibility of impacts is reduced to zero). It is used for extensive decoration of several floors at once, since the lightness of the material does not require the installation of an additional base or reinforcement of existing foundations.

The weight of the material is much lighter than steel, but strength loses. Due to its elegant appearance and lightness, it is used in decorating the walls of cottages and private housing construction (in buildings where there is no high traffic and the possibility of impacts is reduced to zero). It is used for extensive decoration of several floors at once, since the lightness of the material does not require the installation of an additional base or reinforcement of existing foundations.

Aluminum is less degraded by corrosion compared to steel, the layer of polymer coating on the surface, which doubles this indicator, matters. Due to its softness, it is used in places where the risk of damage is minimal. Its cost is higher than a steel base, during manufacture it is easier to plasticize and shape, but it easily loses shape in case of improper operation.

Copper based panels

In the production of this material, roofing copper is used, its thickness is from 0.5 to 0.6 mm. Most of the finished panels have a dark brown color, but depending on the initial properties of copper, it may vary. These panels are rarely covered with a polymer film with a wood pattern, since in its natural form such a coating looks excellent and the material does not need to be protected from the effects of rain, snow, aggressive gases and dust. Copper does not corrode for a long time.

Wood imitation using metal siding

Metal siding is a sheet of galvanized cold-rolled steel with a polymer coating, widely used for exterior decoration.

Metal siding is a sheet of galvanized cold-rolled steel with a polymer coating, widely used for exterior decoration.

Most often, products are manufactured by companies whose main profile is the production of metal. The surface of the sheets is a protective film that allows you to keep the panels safe and sound during transportation.

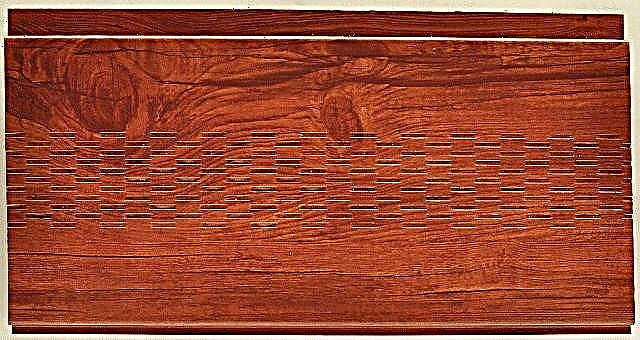

The texture and shape of the material resembles a calibrated log, has a smooth neat surface. In addition to imitation on wood, siding can be similar to the surface of natural stone or shipboard. The ends of the material are equipped with recesses for joining the sheets, while the lower locks are equipped with holes for the discharge of condensate.

When is imitation better than the original: metal siding in wood or timber?

It is believed that wooden houses are the most environmentally friendly and healthiest. In fact, it is difficult to talk about environmental friendliness when, in order for a natural beam to serve for many years, it has to be processed with numerous chemical compounds against moisture, fungus, bacteria and insects.

In addition, it is very difficult to take care of a wooden house so that it retains its original attractive appearance, especially in aggressive environments.

Well, another “but” is the combustibility of natural wood. Metal siding is one of the most flammable, so there is always a risk of fire.

Summing up, we note that the most appropriate option for those who dream of wood trim is metal siding. A huge range of colors and shapes, ease of care and resistance to fire make this material more suitable for cladding at home. The building will turn out beautiful, comfortable, without any frills.

Metal siding walls will not require work to strengthen the foundation structure. Considering that the panel pattern is completely identical to the pattern of natural wood, it can be assumed that it can be used for finishing different types of wood with individual patterns on the log house. The house can be finished in “pine” or “oak” so realistic that it will be almost impossible to notice the differences with the naked eye.

Metal siding for timber - a leader among finishing materials

Metal siding has many advantages compared to the same brick, natural wood or plaster. About the main ones below:

Metal siding has many advantages compared to the same brick, natural wood or plaster. About the main ones below:

- The facade, lined with metal siding under the tree, will not need any care. The material is galvanized, and then treated with polymers that can withstand the effects of precipitation and temperature changes.

- Metal siding maintains color saturation even under the influence of UV rays throughout the entire operational life.

- A house faced with metal siding can breathe.

- The service life of the structure is more than 50 years.

- Metal siding due to galvanizing treatment is not susceptible to corrosion.

Compared to other cladding materials, metal siding can be considered an absolutely environmentally friendly product, not capable of harming the health of home owners.

If necessary, the siding can be painted, cleaned or repaired - the polymer coating will not be damaged during the work and will surely provide the panels with reliable protection.

Metal siding - installation features

A competent approach to the selection and installation of siding will allow using it for facing both modern and fashionable buildings, as well as for restoration work. The material is easily and quickly mounted, it allows you to mask defects on the facade surface, combine and hide from sight the different types of materials used for construction, making the design of the house solid and stylish.

Cladding the walls of the house with siding can be done by yourself. It does not require tremendous experience and skills. The process can be started at any time, regardless of air temperature. The panels can be installed both in the horizontal direction and in the vertical, like a fence.

Installation begins with putting in order the surface of the facade. You will need to get rid of old traces of plaster, cladding, gutters and all kinds of fixtures. Properly cleaned walls will be treated with a soil mixture, and if a wooden house is revetted, then the material will need to be impregnated with antiseptic drugs that can protect its insects and fungi.

The prepared surface must be marked using beacons. The panels are mounted traditionally - on the crate of wooden rails or metal. Of course, it is most convenient to use a ready-made prefabricated metal frame.

Attention! The brackets should be installed in increments of 60 cm in the case of horizontal panel mounting and not more than 1 meter in the case of vertical.

The length of the fastener must be such that the bracket can be fixed at the smallest level with a gap and a protrusion beyond the boundaries of the largest depression.

If a decision has been made on an additional layer of thermal insulation, then you need to adhere to the following point: it is important to lay the insulation close to the brackets with fixation using plate-shaped dowels. In order to protect the heat-insulating layer from blowing, an additional membrane can be used.

The guide profile is installed on the brackets, fixing them with rivets and self-tapping screws. Metal siding is mounted on this profile.

They start from the first row, fixed on the initial bar, after which all the other panels are locked together and fixed with self-tapping screws to the guide profile.

To avoid distortions, you need to constantly check the position of the panels with a building level.

Wood Metal Siding: Useful Installation Tips

Compliance with the main points in the installation process will achieve a high-quality result. It is important to know the following:

- In order not to interfere with natural ventilation, you will need to leave small gaps in places of air circulation - under the windows, near the basement or under the roof eaves.

- The screws should be fixed exactly in the center of the hole, leaving small gaps that will reduce the voltage when the temperature changes. Metal siding must not be overlapped or end-to-end with additional elements.

- A small gap between the ends of the panels and other elements will prevent the cladding from deforming under the influence of temperatures.

In conclusion, we note that the facade, lined with metal siding under the tree, looks fashionable, cozy and neat, without violating the harmony of the surrounding landscape design.

An additional plus is the ability to order panels of the right size to minimize costs and sheath the surface, regardless of its area. Additional elements can also be ordered in tone to the main sheets or other shades to create a contrast effect.

Installation of metal siding under a tree

Metal siding is widely used as a finishing facade material for private houses and cottages. Durable, practical and beautiful material has an affordable price and high technical characteristics. Wood siding, the photo and the price of which allow it to be used for decoration of both small houses and large cottages.

Wood siding features

The recommended length for use as a finishing material is 3-4 meters. Available from half a meter to 6 meters. The width of the siding sheet under the tree is 21.1 centimeters. The useful width is almost 19 centimeters.

Finishing the garage with wood siding

Many people strive to make their home eco-friendly, so they make it of wood or decorate the facade with wooden finishing material. But these materials require careful care from various fungi, molds, mosses, insects and rodents.

Facade of a house with siding

In addition, natural wooden materials have to be treated with various compounds to preserve the appearance of wood. Another disadvantage is that wood is a highly flammable material.

Metal siding under a tree, according to the photo from the catalogs, has a wide range of colors. The form of products and the price are also different. If you want to finish wood with refractory material, then choose metal siding. It allows you to simulate the finish under the beam or other types of wooden finishes with minimal cost.

Wood siding fence

Types of metal siding under a tree

For the installation of this siding, a reinforced foundation is not needed, while the appearance of the finished facade will accurately simulate the natural beauty of wood and give the appearance of a natural finish. Metal siding is made with imitation of various tree species. Imitation of oak or pine generally make the house look like a hut.

The advantages of metal siding

Care for the lined surface when using metal siding is minimal. This material is galvanized during production and then coated with a polymer layer. It does not burn in case of fire. A house with such decoration breathes and is considered environmentally friendly.

Metal siding is protected against corrosion. Sudden changes in temperature do not affect it. The paint covering the siding does not fade. The service life is stretched to half a century, so it can be used to decorate roofs.

Installation of metal siding under a tree

The advantage of siding is that it is quickly and easily mounted, while it is easy to hide any flaws in the construction of the house. During installation, you can additionally insulate the walls with thermal insulation, and so the siding serves as a heater and protect the house from moisture.

Installation is carried out at any time of the year. Fittings for installation are suitable in type and color with decoration. It is possible to fix metal siding in a vertical and horizontal position. Before finishing the walls, any surface should be covered with a protective primer. Siding is fixed with fasteners.

- First, markup is done.

- Axes are applied.

- Then, along the guide profiles, siding is installed.

- The mounting step is 60 centimeters. The length of the fasteners depends on the type of wall.

- Thermal insulation is laid to the brackets and secured with dowels.

- Then guides are attached to the brackets and siding is mounted on them.

- Between themselves the rows are connected by fasteners. Fasteners are made to guides with self-tapping screws.

Finishing with metal siding allows you to make any home more beautiful and warm. You can watch photo of metal siding under a tree, and also compare its price with other finishing materials in order to finally determine. With your own hands you can transform a country house or cottage.

Wood siding

Finishing the building facades with natural wood creates a certain stylistic mood of the building, imitates the atmosphere of classical comfort and gives the viewer an aesthetic pleasure. However, care for natural wooden facades involves regular cleaning and thorough periodic processing of resins.

The market of modern building and decoration materials offers several imitation options for the decoration of facades that completely repeat the structure of the tree. One such material is siding.

Wood siding metal structure

Metal siding under a tree is a high-quality galvanized sheet steel that completely imitates the texture and color of a natural beam by applying a polymer coating to the surface of the sheet, such a coating is also a reliable protection of the material from atmospheric influences.

Thus, the siding metal coating has a number of advantages:

- the siding is not deformed, resistant to rain and wind,

- refractory and durable

- allows you to equip the insulation to your taste and need, and also significantly reduces material costs for facade decoration,

- Siding is environmentally friendly and easy to maintain.

Installation of siding is also a simple and non-material business, having a price that is affordable for the vast majority of users. Price for 1 square. a meter of siding coverage, depending on the region of Russia, ranges from 100 to 1000 rubles.

Description of Siding Wood Coating

The sheet metal coating is multilayer. The basis is the covering sheet metal polyester.

Polyester gives the panel basic thermal protection and resistance to mechanical stress. Under this armor protection is a printed offset layer, which determines the color and texture of the siding wood pattern. The photo shows such a decorative panel in a layered section.

Siding panels are equipped with a set of additional parts for them - ebbs, butt and starting strips, slopes and plugs, siding external and internal corners, also completing a j-shaped profile.

The length of the siding panel imitating wood is from 500 mm to 6000 mm, the width of the panel is from 201 mm to 250 mm. On sale also there are additional elements from 2000 mm to 3000 mm long.

There are also concepts of a useful siding width - visible after installation - and a component of 188 mm with a plate width of 211 mm, and a practical recommended sheet length, convenient for installation - from 3000 mm to 4000 mm.

Since the sheets of “wooden” siding are very light in weight, they do not require additional strengthening of the foundation. The main plus of this type of finish comes from this quality - its situationality.

Features of the installation process of metal siding panels

Cladding the facade and walls of the building with siding sheets involves the implementation of certain preparatory work:

- Dismantling of gutters and gutters,

- Cleaning the walls of old finishing materials, plants, nails,

- Installation of the battens on uneven walls in the event of a height difference of more than 2000 mm on a wall section 10 meters long. The crate for the building for siding is usually made of dry timber, but it is preferable to use a metal grate in this process, which is made with 500-1000 mm pitch,

- After installing the crate, any insulation is fixed in its cells, fixed with a wire or dowels,

- Along the perimeter of the openings, under the eaves, at the corners and at the level of the unevenness of the walls, self-tapping screws are attached to the crate mounting strips with a pitch of 200-400 mm.

Now comes the stage of fastening to the crate of the siding plates themselves, produced without pulling in the direction from the bottom up. In this case, a technical gap of 1.5 mm is left between the metal sheet and the screw head, and 6 - 8 mm between the installation strips and the sheet. The joints between the sheets are closed with special strips. Aluminum material is cut with a hacksaw.

Siding is mounted directly to the wall using self-tapping screws with rubber washers. At the end of the sheathing process, all corners are closed with corners.

Facade decoration with metal siding imitating wood

Metal is a very convenient and practical material for the decoration of facades. However, the tree looks more attractive, the exterior of the house from the boards is more pleasing to the eye. To combine the practicality of the first and the attractiveness of the second material, you can use siding made of metal, which is decorated as wooden.

Modern technology allows you to get a finish that even at close range is difficult to distinguish from a natural lining or logs. Metal siding under a tree has a large list of advantages:

- low cost of material

- light weight simplifies the work, reduces the requirements for the frame, does not create additional load on the foundation,

ease of installation

ease of installation- protects walls from moisture and wind,

- durable

- does not fade, does not change its properties over time,

- resistant to temperature extremes, chemical and physical influences,

- maintainable

- not combustible

- green

- Attractive appearance

- a large selection of types - for oak, pine, under a log or lining, etc.

This type of decoration is often used in the construction of industrial and public buildings, as well as in the construction of private residential buildings. It is much more practical than natural wood, more durable, cheaper, does not need regular painting and other care. And installation is quite possible even for a novice builder.

True, in order for the facade to turn out to be really beautiful, you should treat the work responsibly, paying attention to every detail. It is especially important when working to prevent the appearance of deep scratches on the siding.

Under the layers of paint and zinc, ordinary steel, which, in contact with atmospheric air in a few years, will begin to rust, which will spoil the appearance of the facade.

Preparatory work

So that the siding does not fall off, so that it does not warp, it is necessary to carefully prepare the walls.

- If the walls are lined with wood material, they should be treated with an antiseptic.

If it is stone, brick, plaster, then you need to remove exfoliated fragments, clean the surface, close the cracks.

If it is stone, brick, plaster, then you need to remove exfoliated fragments, clean the surface, close the cracks.- Dismantled drainage elements, communications, protruding window elements (platbands, low tides).

- Often, siding is mounted together with insulation materials. They should be laid before the installation of the crate, if necessary, protected from moisture, wind. Between the insulation and siding, leave 2-3 cm of space for ventilation.

- The crate is attached to the wall with metal suspensions or brackets. The surface should be carefully leveled, because any distortions will be visible after the installation of decorative panels. The distance between the battens of the battens is set in accordance with the dimensions of the decorative panels.

The more carefully, better the preparatory work will be completed, the easier and faster the installation will take place.

Paneling

In general, installation of siding is not difficult, however, it is important to adhere to some rules that will simplify the work:

- Additional elements are installed either together with the main panels, or previously. Installing them after fixing the panels is very difficult, sometimes even impossible.

For fixing, you can use nails (if the crate is wooden) or self-tapping screws. In any case, it is advisable to use a material that is protected from corrosion in order to avoid rust stains on the panels.

For fixing, you can use nails (if the crate is wooden) or self-tapping screws. In any case, it is advisable to use a material that is protected from corrosion in order to avoid rust stains on the panels.- Installation of horizontal panels starts from the bottom. The first row must be very carefully aligned horizontally.

- Screwing on long elements should be done from the middle to the edges.

- A self-tapping screw or nail is driven directly straight, not at an angle.

Do not drive a self-tapping screw or nail to the end, it is necessary that the panel is held loose.

Do not drive a self-tapping screw or nail to the end, it is necessary that the panel is held loose.- A small distance should be left between the rows and between the individual elements in the row so that there is no skew when the temperature drops.

Uniformity of decoration can be guaranteed only if all the material was from the same batch. Therefore, it is better to take a little more panels than is required by calculation. If you have to buy material, the difference in color will certainly be noticeable, since it is impossible to ensure the exact same shade.

Final work

The work cannot be considered finished if all stages, including seemingly small final procedures, have not been completed. In particular, these include:

- slopes and ebbs on windows, doors,

- drainage system

- filing of eaves.

These are not only decorative elements, but also important functional details. They protect the insulation and crate from water, snow, strong wind. If you do not pay proper attention to them, precipitation will fall into the space behind the siding, which will negatively affect the thermal insulation properties of the insulation, and can provoke deformation and destruction of the crate.

Using metal siding under a tree

Metal siding under a tree is a relatively new, but already quite popular finishing material for decorating the exterior walls of buildings. The basis for this finish are sheets of aluminum-zinc steel with a specially treated surface.

On the outside of the metal panel, an offset pattern is applied that imitates a rounded log, lining or timber. After facing the walls of your home with this material, it will look like a classic log cabin.

Design

Metal siding is available in the form of metal panels with a width of 20 cm, a length of 2 to 6 meters. Siding thickness does not exceed 1 mm. Panels “under the tree” are made in the form of a series of curved hemispheres that mimic the wall masonry. In a section, one such panel has the form of a multilayer cake. The first layer is a galvanized steel sheet coated with an anti-corrosion compound. Above is a primer coat.

The top of the panel is covered with a polymer layer. To facilitate assembly, each panel has special latches necessary for simple and reliable mounting of siding on the wall of a building. If there are none, the panels will need to be laid on their own.

In each case, the manufacturer offers the buyer instructions that describe in detail how to fix the metal panel in the selected place.

Benefits

The advantages of wooden structures are undeniable. But what if your house is built of brick or stone? To ennoble your home, make it unique and distinctive, and there is a facing with metal siding under the tree.

In addition to purely decorative advantages, this type of exterior finish has excellent operational characteristics, which are already appreciated by the buyers of this facing material.

Metal siding is not combustible, and does not emit harmful substances either during a long service life or under the influence of weather conditions. Unlike wood, metal cladding does not require constant attention, does not rot and does not become food for rodents and insects. Siding "under the tree" does not change its linear dimensions, the working temperature range of this material is from -50 to + 80 ° C.

The service life of this facing material is on average about 30 years. Basically, the life of a siding depends on its coverage. The polyurethane outer layer allows the metal cladding to maintain its original appearance for 30-50 years, the metal-like siding with a polyester coating faithfully performs its functions for about 25 years.

In addition, metal siding under the tree can be made in various colors. The most popular are “oak”, “light pine”, “light tree”, “dark tree”. The facade finished with siding looks natural and harmonious - visually the metal finish differs little from log masonry.

Installation Features

Typically, each manufacturer offers detailed instructions for the proper operation of their own goods. In order to properly install the siding coating, you must adhere to the instructions described.

For the correct installation of cladding elements, a leveling system is mounted. To do this, you need to build a structure of brackets and wooden blocks with a thickness of about 40 mm. Such a structure allows you to align the various deviations of the external wall of the house from the vertical.

The brackets are fixed to the wall using frame and anchor dowels. To eliminate cold bridges, thermal break-in gaskets up to 5 mm thick are attached to the brackets.

Depending on the direction of further laying of metal siding sheets, horizontal and vertical leveling systems are distinguished. If the facing material is planned to be installed horizontally, vertical components are attached to the brackets. Conversely, if vertical siding is provided, a horizontal leveling system should be installed.

Installation of insulation panels is carried out immediately after the installation of the brackets. The insulation is fastened to the external wall of the building using glass-amide dish-shaped dowels - this ensures the most complete adherence of the insulation layer to the external surface of the building.

The length of the dowels directly depends on the thickness of the selected insulation, the number of fasteners should be at least 5 pcs per 1 m2 of wall. For the purpose of waterproofing and for additional protection of the insulation from atmospheric effects, a windproof plastic film should be laid over the thermal insulation material.

Installation of horizontal elements

After installing the leveling system, various horizontal components are installed:

- mounting strip. This lower part of the future cladding is set using various levels. It is extremely important to give it a strictly horizontal position - after all, it is from the initial bar that metal siding will be installed over the entire surface of the wall,

- corner elements necessary for the design of internal and external corners of the house. These additional structures are also plumbed and secured with auxiliary elements.

Installation of metal siding "under the tree"

Usually conducted from bottom to top. To begin with, you should hook the first panel onto the initial strip, then fasten the upper edge of the siding with screws, starting from the center and gradually attaching the panel to the supporting components of the leveling system. Before attaching the next panel, you need to make sure that the previous structure is tightly fixed along its entire length.

All subsequent siding sheets are hooked on already installed elements and fixed in the same way as the very first panel. In order to prevent various deformations caused by weathering, a gap of 5-10 mm should be left between the ends of the siding and the vertical carriers.

To frame door and window openings, various types of edging are used: platbands, aquilons, sloping slats. Installation of window decoration begins with the installation of the upper parts of the edging, after which the side elements of the window are formed. The siding panel is used so that its ends protrude 2-3 cm from all sides of the window opening.

After that, the width of the window should be noted on the panel, adding about 1 cm around the entire perimeter. These marks will show the locations of the vertical cuts. After that, it is necessary to cut the marked area by marks. In the same way, the siding is chased to the doorway.

The last operation - framing the upper end of the siding. This can be done using the upper tide or corner. The necessary components are fastened with rivets or screws. The pitch of the fasteners is about 40 cm around the entire perimeter of the building.

The cost of metal siding

At first glance, the cost of metal siding is unreasonably high, but detailed miscalculations show that this is a perfectly acceptable option for facing your home. One has only to think about the fact that metal siding does not need to be repaired, strengthened and regularly renovated decorative elements - and the cost of such a facing option will no longer seem excessive.

All the funds necessary for the purchase and installation of metal siding "under the tree" will more than pay off after just a couple of years of operation.

Our site will help you easily navigate the variety of facade technologies used in the construction of suburban cottages, apartment buildings, office and industrial buildings. Here you can find the best solution for arranging the facade of a shopping mall or store, both occupying a separate building, and located on the ground floor of a multi-story building. The information will be useful even to experienced builders and finishers who monitor the latest achievements in this field.

Does not rot and does not deteriorate by living organisms

On metal siding, in comparison with natural wood, moss does not grow and mold does not form, steel siding panels do not “gnaw” bugs.

Photo metal siding at home

Ship board

The most popular type of profile among buyers. Mounted on the facade creates the effect of overlapping boards. The panels give the facade stiffness and resistance to mechanical stress. It is made up to 6 m long.

Metal siding Ship board photo of the house

Woodstock

This type of siding in shape imitates a rounded log. The house, faced with this type of panel, looks like a log house made of natural wood. It is made up to 6 m long.

Photo of a metal siding Woodstock

Ecosteel polymer coating

Ecosteel - decorative polymer coating in color and texture reproducing various varieties of wood. It has different shades and heterogeneity of the structure, which makes Ecosteel siding as close as possible to natural wood.

Aluzinc (Al 55% + Zn 45%), which is part of the coating, provides reliable protection of steel against corrosion and resistance to moisture.

Positive properties of metal siding

Metal under a tree has a lot of advantages and positive qualities, which made its use popular for decoration of external walls of buildings:

- siding is off, interaction with it does not cause toxic poisoning in humans, when heated, for example, by the sun, the panels do not emit harmful substances and chemical compounds,

under the influence of high and low atmospheric temperatures, the material does not change the external qualities, has a small degree of corrosion, cracks from unfavorable factors do not appear on the surface,

under the influence of high and low atmospheric temperatures, the material does not change the external qualities, has a small degree of corrosion, cracks from unfavorable factors do not appear on the surface,- metal siding wall decoration does not require painstaking care, when dusty, the coating is washed with water under pressure from a hose, after which the facade gets an attractive look,

- no surface painting required or another update, metal siding looks great on the surface of the house for many years,

- on the construction market, manufacturers have provided many wood structures in appearance that vary in grain size, color, mimic the different shapes of boards or logs,

- on average, the life of a material is measured over 30 years, a polyurethane coating extends its operating time to 50 years, and the polyester layer lasts about 25 years.

Cost effective wood siding

The use of metal siding for the facade wall decoration can save the owner some money due to the installation and purpose features:

- installation of material on external walls is easy, because of this, many homeowners mount it on their own, without hiring employees, which saves money,

- metal siding with a film coating is cheaper than natural wooden sheathing, but in appearance it does not differ from it, after spending a certain amount, the family receives an attractive house with walls made of wooden logs,

- the owner of the house will definitely save on the restoration of damaged sections of the walls, as there simply will not be any during metal siding,

- installation of a finishing coating made of metal siding will allow to lay an impressive layer of insulation between it and the wall, which will save money for paying for heating services in the winter or reduce the use of purchased fuel and gas.

Installation of metal siding

The calculation is based on the calculation of the length of the panels (5-6 meters). The height for cutting the elements in size is taken from the basement, if it is provided for another finish, or land, in the absence of a basement strip, to the top of the wall under the roof itself. With the horizontal arrangement of the panels, corner profiles, initial window and door panels are placed first, aligning them with the level on both sides, then the length of the panels is measured with the profile going inside.

Preparing the facade for decoration

Inspect the facade from all sides, paying attention to the weak and departed plaster, which needs to be knocked down. Checking the strength of the walls by tapping, it is advisable to strengthen the staggering bricks and blocks with a mortar or hardware, sometimes you will need to make a screed of an old building from a strip in the corner area.

All plants, curly branches are cut, shutters, shutters are removed. For the time being they get rid of drainpipes, cornices, overhangs, ebbs and raincoats. The verticality of the walls is determined for the overall impression, the rectangularity of the corners (external and internal) under 90˚ is checked.

Setting the crate as the basis

Installation of siding on the walls begins with the installation of the lathing from a metal galvanized profile (finished) or a wooden rail in size 10 × 50 mm is used. A wood rail is used because of its low cost relative to the store profile, but over time it can be deformed by pulling the siding cover along with it. To prevent this from happening, before installing the wooden crate is treated with antiseptics or smeared with used oil from the car engine.

Installation of siding on the walls begins with the installation of the lathing from a metal galvanized profile (finished) or a wooden rail in size 10 × 50 mm is used. A wood rail is used because of its low cost relative to the store profile, but over time it can be deformed by pulling the siding cover along with it. To prevent this from happening, before installing the wooden crate is treated with antiseptics or smeared with used oil from the car engine.

The crate is installed perpendicular to the direction of the finishing strips.. Provides angular rails, window starting profiles and door opening strips. To obtain a harmonious appearance, they try to put all the vertical or horizontal supports in the same plane, without protruding elements. Horizontalness is checked by level, verticality - by plumb. You can use modern laser tools, which will give greater accuracy.

To mount the rails or mounting profiles, special brackets are mounted on the wall, most often they use the EU bracket from the drywall mounting system. It is fixed with a dowel with a self-driving or twisting self-tapping screw into the wall of the building. The rail is inserted inside and attached to the sides of the bracket with self-tapping screws on the tree (rail) or “fleas” (profile). It is recommended to leave an intermediate step between the support rails of 40-50 cm.

The insulation is cut into pieces by the width of the step between the crate, it is fixed to the wall with special dowels, which have an expanded part in the form of a mushroom (to support loose insulation). If sheet insulation is used, for example, polystyrene foam or polystyrene foam, then it can be glued to the wall with building glue, if the wall surface is strong and does not peel. A diffuse film is attached to the insulation layer from above.

The film is sold in the store and, depending on the protective qualities, has a different price. Sometimes, in order to save, the insulation is covered with ordinary polyethylene. For fastening the film using a stapler, wire or screws. It is advisable to join the joints of the film a little overlap and glue with tape to create a continuous barrier to moisture or moist air.

Setting the launch strips

The installation of all the following strips depends on the correct installation of the first strip of metal railings under the tree:

before fixing it check the horizontal level,

before fixing it check the horizontal level,- the first starting bar is placed at the bottom of the wall, while it is placed 4 cm above the first finishing strip (its lower edge),

- for fixing use dowels, screws or other hardware, depending on the material of the walls,

- after that mark the installation of corners, window and door strips, calibrate them with a plumb line and attach to the crate with screws.

Fixing the decoration panels

The first lower strip is latched with a lock on the starting plate and fixed to the crate with screws. You can use hardware only after the strip is firmly latched into the castle along the entire length. For self-tapping screws, special openings are provided in the panel body into which they are inserted. The holes have a slightly larger diameter so that the metal siding panel can move millimeters as a result of heating.

The screws do not tighten to the end, leave free 1-2 mm. Cut the panels to size so that they are freely inside the strips and corners. The free space at the ends (to the inside of the outer corner) should be no more than 9 mm, given this gap in total from both sides. The last bar (finish) is placed directly under the eaves of the roof.

If with a large length of the facade a docking bar is required, then it is placed on the crate and measured in all parameters to create a beautiful appearance. To set the strip under the window opening, use the finish bar. First, apply it to doors or windows, note the location of the platbands and window parameters.

All marked circuits are carefully cut out with a grinder or a hacksaw, after which the prepared panel is inserted inside the window cladding, snapped onto the panel below and fastened with self-tapping screws. Similarly cut and fasten the finish bar under the cornice.

Common Errors

A poorly prepared facade surface does not allow to firmly fix the elements of the crate, they eventually warp, loosen and pull the assembled panels along, disrupting the appearance. A large step between the vertical battens of the crate leads to a visual sagging of the panels. If the siding is placed vertically, then its laying begins from the middle of the wall and gradually moves to the corners, otherwise you can get an overrun in size.

With a horizontal arrangement of siding panels, the sheet is fastened first in the center, then the left and right edges are exposed and fixed, taking into account the horizontal level. If you do not leave a distance under the head of the self-tapping screw, but fix it point-blank, then the structure will creak, click or the integrity of the metal siding under the tree will be creaked when heated by sunlight.

With a horizontal arrangement of siding panels, the sheet is fastened first in the center, then the left and right edges are exposed and fixed, taking into account the horizontal level. If you do not leave a distance under the head of the self-tapping screw, but fix it point-blank, then the structure will creak, click or the integrity of the metal siding under the tree will be creaked when heated by sunlight.

The use of metal siding for interior walls is unacceptable. Material indoors does not breathe, condensation appears on it, microclimate indicators deteriorate.

Wood siding metal description

Wood siding can be several species:

- under the log (block house),

- under the beam (euro-beam),

- shipboard.

Different manufacturers may have different sizes of plates, their color, thickness and other specifications.

Unlike natural wood, metal sheets do not need to be treated with special compounds from insects, moisture and ignition.

Plates under a tree look like a series of arched hemispheres that mimic wood masonry. If you cut one panel, then it has several layers:

- galvanized steel,

- anti-corrosion layer

- primer coat

- paint,

- polymer coating.

So that the installation of metal siding under the tree does not create difficulties, each panel is equipped with a special latch, with which it is firmly attached to the wall of the building. If there are none, then the plates will have to be laid on their own.

Ecosteel Coating Colors

Bog oak - A classic duet of cold shades of brown. A stylish option for decorating a house with wood siding for lovers of the classics, compares favorably with different textures: concrete, stone, brick. Such a siding will become the accent of the exterior, if you just supplement it with green spaces around the perimeter, the house cannot be distinguished from the project of a famous designer.

Bog oak - No less attractive color scheme for exterior decoration with wood siding. Sunlight will be scattered across the glossy surface of the panel, causing shades to play with new tints. Noble cold brown will declare the excellent taste of the owner of the house. Add to this a few flowering bushes at the entrance and small pebble chips around the perimeter. Voila! - Here is a European-level project that the neighbors will envy.

Golden oak - a warm brown shade with streaks of red will favorably emphasize the architecture of the building: pay attention to the elegant finish of the main entrance, pediments. Pleasant to the eye, it will add coziness to the infield. If you plant maple, mountain ash and a couple of birches nearby, just imagine what picture will appear in the fall! Bright red and yellow leaves on the background of the golden panels of the home - here it is, a harmonious picture of the hearth.

Cedar - at least four shades are combined in this color: from deep brown to dusted opal. Imagine the texture of a natural tree: you run it through your hand, feeling every vein, your fingers feel pleasant warmth - this is exactly how your house will be finished with metal siding in the color “Cedar”. If you like medium color saturation, a soft glow from the inside is ideal for you.

Pine - unobtrusive light brown color combined with the natural texture of wood - a great choice for home decoration. It looks equally good both with contrasting roof colors (black, burgundy) and with original solutions. If modern loft and empire styles are not about you, take a look at this color in a glossy, matte, as well as textured version.

Outside corner

plain - it is used for finishing the external corner joints of the siding, has a simple 90 ° angle shape, is mounted on top of the siding, and is screwed with screws.

complicated - it has the shape of an angle of 90 ° with two grooves, it is installed on the subsystem before the installation of metal siding, the place of fixture will be hidden.

Inside corner

plain - a simple shape of the angle of 90 °, designed to overlap the internal corners on the facade of the building, mounted on top of the siding, screwed with screws.

complicated - a profile with two grooves and an angle of 90 °, is mounted on a subsystem, then a siding is inserted into it, the place of fasteners will be hidden.

Finishing bar

simple - a flat curved bar, designed to hide the edges of the panels of the upper row.

complex - is necessary for fixing the edge of the upper row of siding panels, as well as window and door openings, has the shape in the form of the letter J.

Initial bar - a profile with a curved edge on one side, used for mounting the first row of metal siding panels, the panels will completely close it.

Docking Bar - a profile with two curved edges or grooves, used for joining panels of metal siding under a tree vertically or in obtuse angles.

Thermal conductivity

Wood siding does not have high thermal conductivity. Even if you mount the plates on a ventilated facade system, the material will not maintain high heat resistance. To increase this indicator, when using metal siding, it is recommended to additionally insulate the walls with an insulator - basalt cotton wool, polystyrene foam, foam insulation, glass wool and others.

Weight and dimensions

The thickness of one sheet, depending on the manufacturer, can vary within no more than 1 mm. The length, as a rule, has a value equal to 200 to 600 cm, and the width is from 20 to 25 cm.

The weight of the material is approximately 3.5 kg per 1 m 2. This is a fairly high indicator, therefore, during installation, special attention is paid to the strength of the metal frame, which is attached to the outer wall of the building, and then sheets are installed on it.

For example, metal siding "shipboard" sizes:

- thickness - 1.4 cm

- the width of one panel is up to 26 cm,

- length - up to 600 cm.

Ruukki

Finnish quality metal siding. On the market for more than half a century. The “shipboard” made by this manufacturer is characterized not only by a long service life, but also by high technical indicators. Ruukki also uses all types of protective coatings and offers models with a smooth or embossed surface, which can be either matte or glossy.

Alcoa

American metal siding. The basis of the plates is aluminum. Products are very popular far beyond the US due to their low cost combined with high quality. In addition, aluminum is considered to be much stronger than galvanized steel and lighter in weight, which does not imply a weight load on the supporting structure of the building walls.

Corus group

British-Dutch metal siding. It is also of high quality, like its main competitors in this niche of facing materials. All panels are covered with a protective layer. A variety of colors allows you to realize the most complex design ideas.

Grand line

Metalworker is a trademark of Grand Line of domestic production. Ecobrus - metal siding "Grand Line", which is very popular for cladding any building, whether it is a private cottage or industrial premises. The protective coating can be completely different depending on the preferences of the buyer. Color shades of the plates include more than 50 different options, which satisfies even the most demanding requests.

Metal profile

Another domestic manufacturer of metal siding, whose main advantages are the high quality of manufactured products in combination with an affordable price.

The assortment of imitation oak, pine, maple and others.

Foundation preparation

Preparation of the base of the walls is carried out the same way, whatever type of cladding you choose.

Although this process does not affect the strength of the facade, it helps to avoid many undesirable consequences - cracks, holes, chip formation, masonry destruction, mold and fungus on the main wall.

Therefore, before proceeding with the installation of metal siding, examine the walls, identify the main disadvantages and try to eliminate them:

- removal of old plaster or paint,

- sealing holes, chips, cracks,

- masonry restoration,

- plaster,

- putty,

- priming the walls.

Wall insulation

Thermal insulation of walls with metal siding for the facade can be performed with any available material - polystyrene foam, foam insulation, glass wool, mineral wool, basalt insulation.

The most popular method is material that can be cut, since the distance between the planks of the crate does not allow you to mount an insulator whose width exceeds 30 cm.

Installation of lathing for metal siding

The crate can be of two types:

The most durable option is a crate made of metal elements. For its installation, galvanized profiles are used that do not need to be treated with anti-corrosion solutions. It is recommended to use it if the main walls are erected using brick, cinder block, as well as gas or foam concrete.

Crate elements are installed in increments of 30-40 cm, and in regions with bad weather conditions, for example, strong gusts of wind, the distance should be reduced to 20 cm.

When mounting the structure, take into account the fact that a heat insulator will be installed. The fastening of metal profiles is carried out using suspensions, which in turn are attached to the wall of the house with dowels.

For wood crates, any wood whose moisture content is not more than 12-15% is suitable. It is better not to use raw material, because when it dries it can “lead”, and the siding will “move out” after it. Prepare the guides in advance with refractory mixtures, as well as insect and rot solutions.

Setting the starting stripe

The evenness of the entire facade finish depends on the correct installation of the initial level for any arrangement of metal siding panels.

If you set up markings with large horizontal errors, then it is likely that the metal siding will gradually move out, and errors in the installation of vertical profiles can even lead to the collapse of the entire structure.

The device is obtuse, sharp corners and an H-shaped connector

All corner elements - external and internal corners, are fixed on a plumb line.

As fasteners use screws or rivets. The distance between the fasteners is 30 cm on both sides. Similarly, an H-bar is installed in places where the joints are planned.

How to bypass siding windows and doorways

Installation of siding around window openings is performed as follows:

- take a piece of metal plate that you don’t need,

- measure it so that the edges protrude on both sides of the opening,

- mark the width of the opening on it, increasing it on both sides by 1 cm - these will be the places of vertical cuts,

- fix a piece of the panel on the side of the opening and make marks on it 5-6 mm below the window sill and above the upper edge - these will be the places of horizontal cuts,

- Transfer the layout template to the metal siding panel and make the necessary trim.

Installing panels around the doorway is done in the same way. All places of cuts and cuts on metal siding must be treated with special tinting paste.

Caring for metal siding

Caring for metal siding under a tree does not require special attention and the use of special cleaning agents. As a rule, the surfaces of the plates are able to self-clean during rain. In case of severe contamination, they are treated with a hose connected to the water supply and a long brush. Only in some cases a general washing of metal siding is required, but this only applies to multi-storey buildings, where washing involves hiring special teams of climbers and appropriate professional equipment.

Summing up, we can say that metal siding under a tree is an ideal solution for the construction of a new and restoration of the old facade of a building. It has high technical characteristics, a long service life, as well as an attractive appearance, which is difficult to distinguish from natural wooden masonry.

Maintenance of the panels is quite simple - just wash them with clean water from a hose or wipe them with a soft cloth.

Metal siding is resistant to mechanical damage, however, it can heat up in the sun, so it is better not to lean against it in the heat. Installation of siding can be done with your own hands on a wooden or metal crate.

ease of installation

ease of installation If it is stone, brick, plaster, then you need to remove exfoliated fragments, clean the surface, close the cracks.

If it is stone, brick, plaster, then you need to remove exfoliated fragments, clean the surface, close the cracks. For fixing, you can use nails (if the crate is wooden) or self-tapping screws. In any case, it is advisable to use a material that is protected from corrosion in order to avoid rust stains on the panels.

For fixing, you can use nails (if the crate is wooden) or self-tapping screws. In any case, it is advisable to use a material that is protected from corrosion in order to avoid rust stains on the panels. Do not drive a self-tapping screw or nail to the end, it is necessary that the panel is held loose.

Do not drive a self-tapping screw or nail to the end, it is necessary that the panel is held loose. under the influence of high and low atmospheric temperatures, the material does not change the external qualities, has a small degree of corrosion, cracks from unfavorable factors do not appear on the surface,

under the influence of high and low atmospheric temperatures, the material does not change the external qualities, has a small degree of corrosion, cracks from unfavorable factors do not appear on the surface, before fixing it check the horizontal level,

before fixing it check the horizontal level,